Question 89: What are the typical problem areas for CCR catalyst circulation loops? What are the most reliable valve types? How frequently do you conduct fines surveys and what is a reasonable range for fines make?

GRUBB (Chevron U.S.A., Inc.)

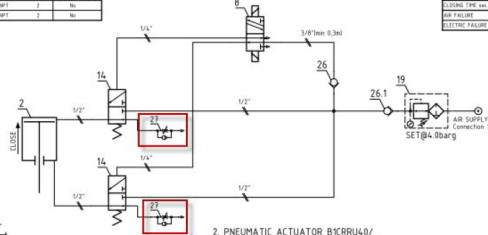

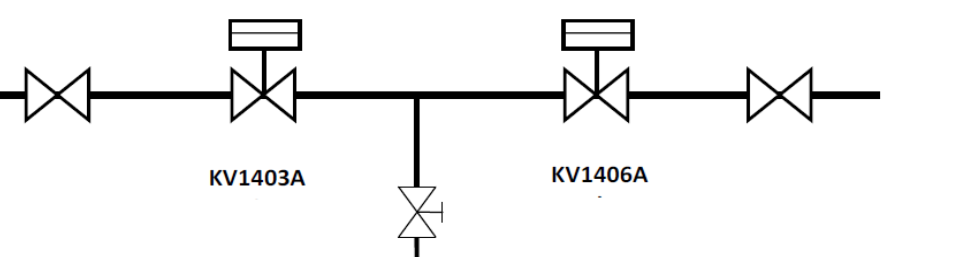

My experience here is with the design of a new unit in Pascagoula. So we went to the other CCRs within the Chevron system and asked this question already on how to increase our reliability with that project. This is a roundabout answer arranged from all the different operating ones. On the valve types, I’ll just state that all of Chevron’s experience is with the UOP designs and what we do is we specify soft seat on the “V” notch ball valve wherever the catalyst flow must be stopped. We use a double-seated plug and globe “G” valves on the vents and spring loaded “B” ball valves for the gas tight seal on the catalyst transfer line. We prefer that we have a spline driver connecting the shaft to the ball. That increases reliability there.

For the valve maintenance, we arrange for the operators to do a survey once per week following a cycle. Our biggest reliability impact we have seen throughout our system is when we find that one of the valves is bad, then we replace all three. We have found that if one was that bad, then shortly thereafter the other ones would go bad. That was our biggest impact. We also avoid the range now and we make sure that we have spares on site, so we can replace them when needed.

Some other things that we do for monitoring to increase the reliability are that we monitor the lift gas velocities pretty closely so we can control any erosion. We survey once a week to set the elutriation gas flow rate to get 20% whole pills. We have found that the disengaging hopper, the PSVs, don’t re-seat very, very well because of the dust that’s usually associated there, so that’s a problem sometimes. The dust collector bags can get holes; and when that happens, then it messes with the blowers and reduces the reliability of some of that equipment. So we’re working on putting in some DP gauges to try to help detect whenever we get a hole in some of the bags. We monitor the temperature in the transfer legs to try to minimize any plugging that might occur. We watch the surge hopper purge rates. Another thing we do is whenever we do shut down the regeneration section, we bar over the blowers each day that they’re down. Another thing we do when we shut down is we like to move two batches of catalyst on the shutdown so that you protect the scallops in the reactors from the cool-down.

Some operating units have noticed on startups that they potentially, if they feel like they see a plugging issue occurring, they’ll do five short 10-second lifts to heat up the system. It appears that the operators have prevented a plugging situation, so we like to do that.

QUINTANA (Valero Energy Corporation)

We’ve seen catalyst circulation issues arise through a variety of mechanisms. Mechanical issues, such as protrusions into the catalyst flow path, whether through misalignment of ball valves or even simple housekeeping issues like foreign material remaining from construction or maintenance activities in the catalyst piping. You can also have issues if you have any of your catalyst lift equipment or lift lines eroding over time. All these can lead to higher fines make.

We’ve seen quite a bit of erosion in some of our older CCR units on the lift lines, especially at the return bends at the top of the reactors. This may be from exceeding the recommended lift velocities. But over time, as those erode and you actually can come close to holing through, you get some pretty sharp edges that will increase fines make substantially.

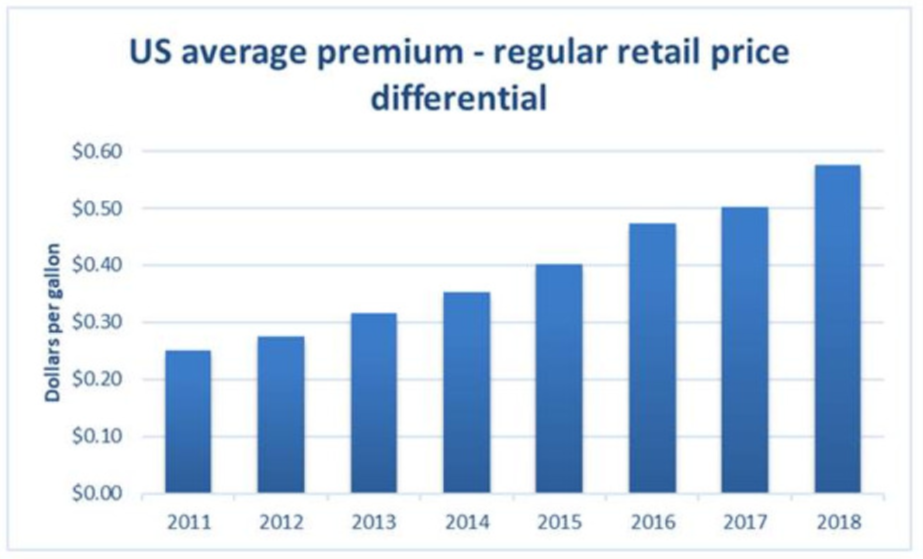

Alternately, catalyst that’s too hot, has excessive moisture or contains fines won’t flow very well. That can be caused by improper operating conditions in the regeneration and cooling zone, the drying zone, elutriation system or excessive lift gas velocities. Generally, what we’ve found with the wide range of units we have is that some CCRs circulate as little as 200 pounds per hour of catalyst and some as high as 3,000 pounds per hour. The larger units with higher circulation rates are more sensitive to these issues.

Certainly, we echo Rick’s comment regarding withdrawal of catalyst from reactors at shut downtime. Our rule of thumb is about 3% of the catalyst inventory in the reactors is about what you would take out. So depending on what the lift size in an atmospheric lock-hopper might be, you might withdraw that much. If you have a newer cycle max-type regenerator, you might move a certain amount of catalyst at a minimum rate for a certain amount of time in order to achieve that target.

Essential to making any valve work is applying a rigorous quality control programs for all aspects of valve maintenance and inspection, including a final inspection adjustment immediately prior to reinstallation of any valve into the unit. We normally take monthly or quarterly detailed fine surveys, along with regular daily visual inspections of fines produced. But if at any time fines production increases relative to the historical baseline, then we’ll carry on a higher frequency of fine surveys until the cause of incremental fines is identified and corrected.

As for what constitutes a reasonable fines level, we find that is unit specific. A reasonable proxy is really the original guaranteed fines level that came from the licensor when the unit was built new.