Question 96: What is the CO boiler start-up and shutdown sequence with respect to the FCCU start-up and shutdown timing? What are the reasons for this sequence?

BROOKS (BP Refining)

As I mentioned briefly in an earlier question, most of our FCCs with CO boilers start-up with the CO boilers bypassed. If we run partial-burn on any of these FCCs, we tend to start-up in full-burn at reduced rates. Once the feed is in the unit and considered stable, most sites will cut into their CO boiler with the process flow. Our partial-burn units will then move back into parital-burn. Basically, the CO boilers are started up while the FCC is routed to the bypass stack. As you start up the CO boiler, you fire it initially on fuel gas. Then when the FCC flue gas flow is brought back into the CO boiler, you reduce the fuel gas firing accordingly. We do this in order to prevent running directly through the CO boiler when transitioning from full-burn to partial-burn, which can cause issues with a combustible environment.

Shutdown sequences are similar. We shut down the unit, move all of our partial-burns into full-burns, take flow out of the CO boiler, and then route it to the bypass stack. We have some units that rely on their CO boilers to make steam for the rest of the refinery. Thus, we will go out the bypass sack, isolate it with a blind, and then continue running it online with fuel gas. It is fairly basic, but most of our CO boilers are run that way.

SCHOEPE (Phillips 66)

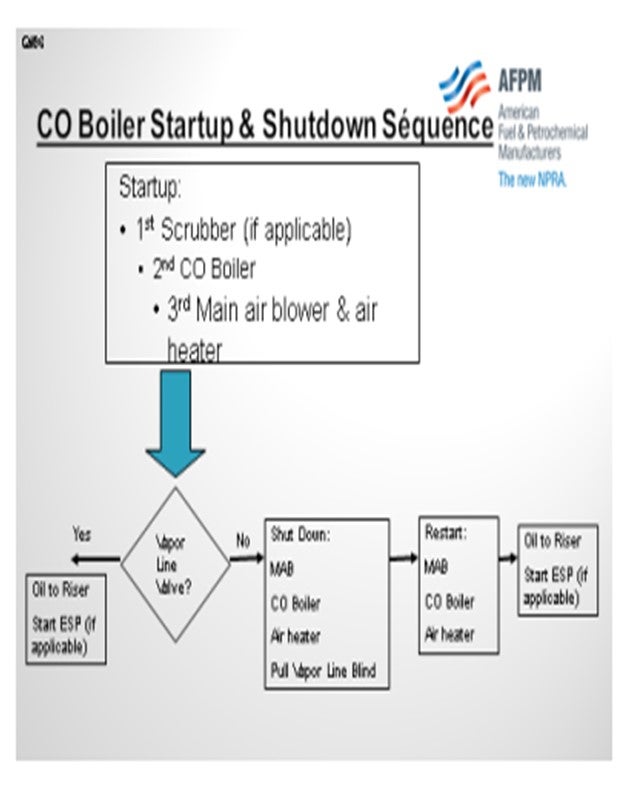

In our units, the CO boiler is one of the first pieces of equipment that is started and one of the last pieces of equipment taken down, unless you have a flue gas scrubber. If you do have a scrubber, you will usually start the scrubber first and then the CO boiler. In some sites, the main air blower partially depends on the steam supply from the CO boiler. We already went through the whole vapor line scenario. If you have a valve, you can then go directly to catalyst loading and oil-in. If not, then shut down all of this equipment, pull the vapor line blind, and start up the equipment again.

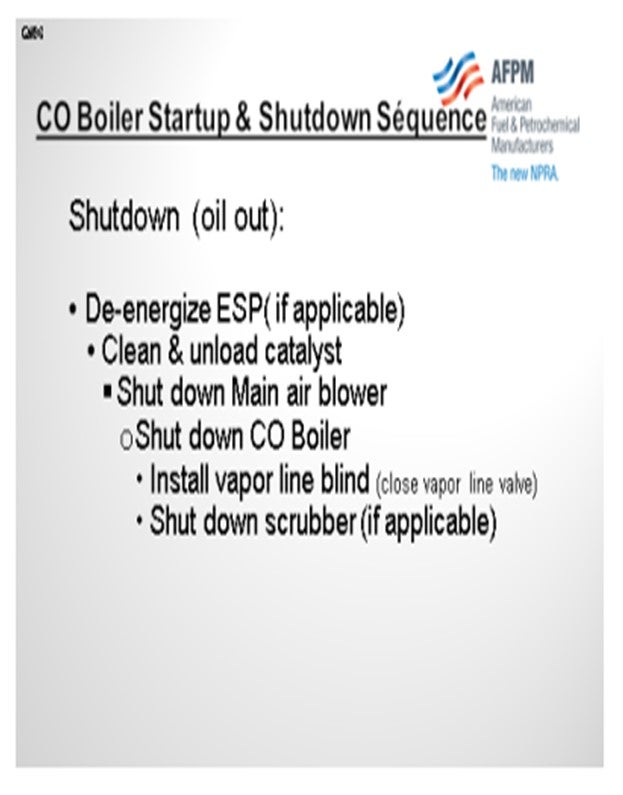

In terms of a shutdown, which is shown on the next slide, our units typically de-energize the ESP first. After that, catalyst is circulated to decoke the catalyst. The catalyst is then unloaded, and the air blower is shut down. Shut down your CO boiler last. That way, you will still be supplying steam to the refinery and your main air blower while minimizing potential CO emission during this catalyst cleanup step.

LALL (UOP, A Honeywell Company)

Although UOP does not dictate when the CO boiler is to be started up on auxiliary firing, our procedure specifies that the FCC is to be started up in complete combustion with flue gas diverted to the bypass stack. The flue gas is diverted to a CO boiler only after the feed has been introduced to the FCC and the regenerator operation has transitioned from complete combustion to stable partial-burn. UOP considers this to be the safest way for the following reasons: 1. There is a minimal chance of the presence of unburned hydrocarbons being in the flue gas as a result of unsuccessful lighting of the torch oil. 2. The feed is routed to the FCC, and the FCC operation and pressure balance is steady. In the event of a pressure upset, there is the potential of a reversal, which could introduce a significant concentration of hydrocarbons into the CO boiler and cause a major upset. 3. The transition from full- to partial-burn is very dynamic and may be unpredictable. UOP’s preference is to not swing from the bypass to the CO boiler during this unstable situation until after feed is introduced to the riser at low rates and after the regeneration has transitioned from full-burn to stable partial-burn. Some refiners may have an ESP or wet gas scrubber downstream of the CO boiler. They must run these whenever feed is in the unit, and they could be forced to run through the CO boiler in this situation; but from a safety perspective, it is not preferred.

PIMENTEL (CITGO Petroleum Corporation)

Our experience is very similar. Our CO boiler start-up and shutdown is relatively independent from the FCC. Actually, we start the CO boiler in advance of the FCC mainly because our air blower turbine requires the steam to run at full capacity. To do this, of course, your boiler must be equipped with an adequate number of auxiliary fuel burners. For the same reason, the FCC shuts down in advance of the CO boiler. The boiler can be kept in operation through the bypass, as was already explained. We shut down later for scheduled work. If there is no work scheduled for the CO boiler during the turnaround, it can continue to run isolated through the entire FCC outage.

MICHAEL LEMESHEV (Zimmerman & Jansen)

At some point, everyone on the panel indicated that during the start-up, you begin to divert some flow into the CO boiler. Is that correct?

BROOKS (BP Refining)

We do not divert any flow to the CO boiler until the FCCU unit is started up.

BROOKS (BP Refining)

BP sites with CO boilers typically start their FCCUs with the CO boilers bypassed. Our partial-burn units will start the unit up in full-burn operation (at reduced feed rates). When feed is in the unit and the unit is considered as stable, sites typically bring the CO boiler into the process flow. Partial-burn units then move from full-burn back to typical partial-burn operations. The CO boiler is typically started up on fuel gas while the FCCU flue gas is routed to the bypass stack. Fuel gas is cut back as the FCC flue gas is routed through the CO boiler. The CO boiler must be fired with fuel gas before the FCC is brought back into partial-burn service in order to avoid an explosion risk. Shutdown sequences are similar. Partial-burn units are brought into full-burn operations (at reduced feed rates) before the CO boiler is taken out of FCC service. Some of our units rely on the CO boiler to provide steam to the refinery. These units typically increase fuel gas firing when the FCCU is routed through the bypass stack on shutdown.

SCHOEPE (Phillips 66)

The start-up sequence is different for units with electrostatic precipitators (ESPs) and units with flue gas scrubbers. Units with ESPs typically start the CO boiler first while units with flue gas scrubbers start the scrubber before the CO boiler is started. Some sites need the steam from the CO boiler to drive the main air blower turbine. After the CO boiler start-up, the main air blower and the in-line air heater are started and the unit is heated for refractory dryout. After refractory dryout, the start-up paths diverge for units with vapor line isolation blinds in comparison to units with vapor line isolation valves.

Units with vapor line isolation blinds steam out the reactor and then shut down the main air blower, the inline air heater, and the CO boiler in preparation for pulling the vapor line isolation blind. After the isolation blind has been pulled, the CO boiler the main air blower and the inline air heater are started up again and the regenerator is heated in preparation for catalyst loading. Units with a vapor line isolation valve simply keep the CO boiler, the main air blower and the in-line air heater running and proceed directly from refractory dryout to catalyst loading.

Just before the introduction of torch oil, the CO boiler combustor temperature is maximized in order to minimize the CO emission during the operation with torch oil.

During shutdown, the CO boiler is usually tripped after catalyst has been unloaded. This way, steam is provided to drive the main air blower and the potential for CO emission is minimized.

PIMENTEL (CITGO Petroleum Corporation)

In our experience, the CO boiler starts up in advance of the FCC, since the air blower turbine depends on the steam from the CO boiler to run at full capacity and the CO boiler is equipped with an adequate number of auxiliary fuel burners. For the same reasons, the boiler is kept in operation (although at a reduced rate) until after the FCC is completely down; exporting steam to the grid and shutting down when required to perform the scheduled maintenance work. If no maintenance work is required, the CO boiler remains in operation during the FCC outage.

LALL (UOP, A Honeywell Company)

Commissioning of the FCCU requires ample steam availability especially for start-ups. In FCCUs equipped with CO boilers, the CO boiler is a major producer of HP steam for the refinery in normal operation. The timing of the CO boiler start-up may be dependent upon the need of the CO boiler to supplement the refinery steam system during start-up of the FCC.

Although UOP does not dictate when the CO boiler is to be started up on auxiliary firing, our procedures specify the FCC is to be started up in complete combustion with the flue gas diverted to the bypass stack. The flue gas is diverted from the bypass stack to the CO boiler only after the feed has been introduced to the FCC and the regenerator operation has transitioned from complete combustion to stable partial-burn mode. UOP considers this to be the safest way as the unit will be stable before the diverter valve is directed to the CO boiler for the following reasons:

a) There is minimum chance for unburned hydrocarbons in the flue gas from unsuccessful lighting off of torch oil.

b) Feed is routed to the FCC riser and the FCC operation and pressure balance is steady - in event of a pressure upset there is the potential of a reversal which could introduce a significant concentration of hydrocarbons into the CO boiler and cause a major upset.

c) The transition from full-burn to partial-burn is very dynamic and may be unpredictable. UOP preference is not to swing from bypass to CO boiler during this unstable situation until after feed is introduced to the riser at low feed rate and the regeneration has transitioned from full-burn to stable partial-burn operation.

Some refiners may have an ESP or wet gas scrubber downstream of CO boiler and must run these whenever feed is in the unit and may be forced to run through the CO boiler in this situation, but it is not preferred from a safety perspective.

If the CO boiler is required to be commissioned in early in the overall FCC start-up sequence to supplement refinery steam production, this will most likely occur before start of the air blower. The CO boiler will be operated on auxiliary firing (refinery gas) at start up with forced draft fans in operation. Start-up will be performed with the electric driven fan, supplying maximum combustion air and the burner(s) at minimum load (when no HP steam is available for the steam turbine users). The steam demand on steam network determines the degree of firing.

The CO boiler can be shut down any time after feed is removed from the unit to ensure any residual CO production from coke combustion is converted unless the CO boiler is required for refinery steam production. The procedure following feed cut out is to open the diverter valve to the bypass stack and reduce burner load till minimum load, then stop the auxiliary firing and burner(s).