Question 96: What are your experiences using SOx reduction additives formulated with lower rare earth content?

Ray Fletcher (Intercat)

Cerium oxide functions as an oxidant and oxygen carrier: the mixture of two oxidation states Ce(III) and Ce(IV) creates defect sites in the crystal structure where oxygen ions are missing (oxygen vacancies) – these get filled up in the regen and ceria acts as a kind of monatomic oxygen sponge. Monatomic oxygen is more reactive than O2 hence ceria catalyses oxidation reactions. Also mixing in the regen is effectively improved as oxygen is transported around the regen as the particles move around.

Most other oxidants don’t do this (e.g., Pt promotes oxidation when two molecules meet on its surface, it doesn’t sponge the oxygen). So, ceria does play a rather special role. Simply decreasing the amount of ceria works to some extent, but clearly a point will be reached where efficiency drops off.

Intercat has developed and commercialized SOx reduction additives containing 50% less cerium. What Intercat has done is to “extend” the functionality of ceria by proprietary methods to improve the overall oxidation activity of the additive thereby allowing the ceria content to be decreased at equivalent performance. At present, there are now over 28 users of this technology. In every application the lower concentration cerium additive has performed equal or slightly better than the standard SUPER SOXGETTER.

Further, Intercat is utilizing proprietary technology developed within its new owner, Johnson Matthey, for further enhancements in cerium dispersion together with new oxidation packages which will enable a 75% or greater cerium oxide reduction. These technologies include the careful construction of the physical structure of the microsphere, deployment of manufacturing technology which controls both the location and the local concentration of the cerium particles plus the addition of co-promoters to the additive. These techniques have made it possible to improve the overall oxidation activity of the additive thereby allowing the ceria content to be decreased while maintaining equivalent SOx removal performance. Two trials of this technology have been initiated and are being base loaded into two North American refineries now.

Intercat, as well as other additive suppliers, has developed rare earth free SOx reducing additive. These additives of course are lower in cost but generally require much higher concentrations in the circulating inventory. Depending on the composition of the additive this may lead to cracking dilution and possibly loss in product yield. However, it is recommended that refiners employing SOx reducing additive consider these technologies in addition to the high activity additives described moments ago.

Matthew Meyers (Western Refining)

Western Refining LLC has recently trialed several SOx reduction additives with lower levels of rare earth. The first was at half the typical rare earth levels. At 1% dosing, the result was a pickup factor of roughly 15. The second addition had zero rare earth and provided a pickup factor of roughly 5 at close to 3% dosing.

Eric Griesinger (Grace Davison Refining Technologies)

Grace Davison’s SOx reduction additives, formulated with lower rare earth content to lessen the impact of hyperinflationary costs associated with rare earth compounds, have gained wide acceptance. Within Grace’s portfolio of SOx additive products and its accounts, customers that were able to make a change to lower rare earth formulated SOx additives have done so. FCCU locations currently operating under EPA Consent Decree trial protocol have remained with the original formulation available at the start of their trial periods. Only two additional refineries are in the midst of evaluations between Grace’s Super DESOX® additive and Grace’s alternative products. Otherwise, all of Grace’s globally situated customers, existing and newly acquired, are utilizing SOx additives formulated with lower rare earth content. Grace offers three new SOx reduction additives: Super DESOX® OCI, Super DESOX® MCD, and Super DESOX® CeRO. Super DESOX® OCI, optimum cerium input; mitigates costs associated with rare earth compounds, while demonstrating on par pick-up-factor efficiency to Super DESOX® additive. Super DESOX® MCD, maximum cerium dispersion, further reduces rare earth cost exposure, yielding suitable and cost-effective balance between SOx transfer ability and slightly increased dosing rate. Additionally, Super DESOX® CeRO is formulated without rare earth compounds. All three of these new products build on the success of Grace’s Super DESOX® additive performance. These offerings provide refiners with a range flexible option, enabling a balance between rare earth inflationary exposures and dosing rates, to achieve SOx emission compliance.

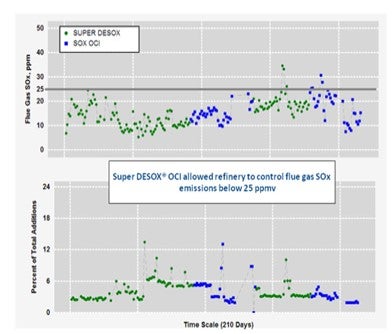

Below is an example of a refiner that historically utilized Super DESOX® and then switched to Super DESOX® OCI. Observed is the ability of Super DESOX® OCI to continue controlling SOx emissions within limits, at comparable dosing rates as was the case with Super DESOX®. Utilizing Super DESOX® OCI over Super DESOX® can result in a SOx additive cost reduction roughly 35%.

Additionally, Grace Davison’s laboratory scale research indicates that the partial burn environment performance of Super DESOX® OCI and Super DESOX® MCD is similar to that of Super DESOX®. Please contact your local Grace Davison sales and technical service representative for additional insight specific to your application.