Question 90: Can ZSM-5 be used to make propylene from high metal resid feeds? What is the effect of nickel and vanadium on this kind of operation?

AVERY (Albemarle Corporation)

ZSM-5 usage is widely used in FCC units trying to maximize propylene. ZSM-5 usage is just as popular in resid units as it is with gas oil units. We have seen high propylene yield units, resid units with feeds greater than 6 Conradson carbon residue, and e-cats that exceed 10,000 ppm nickel plus vanadium.

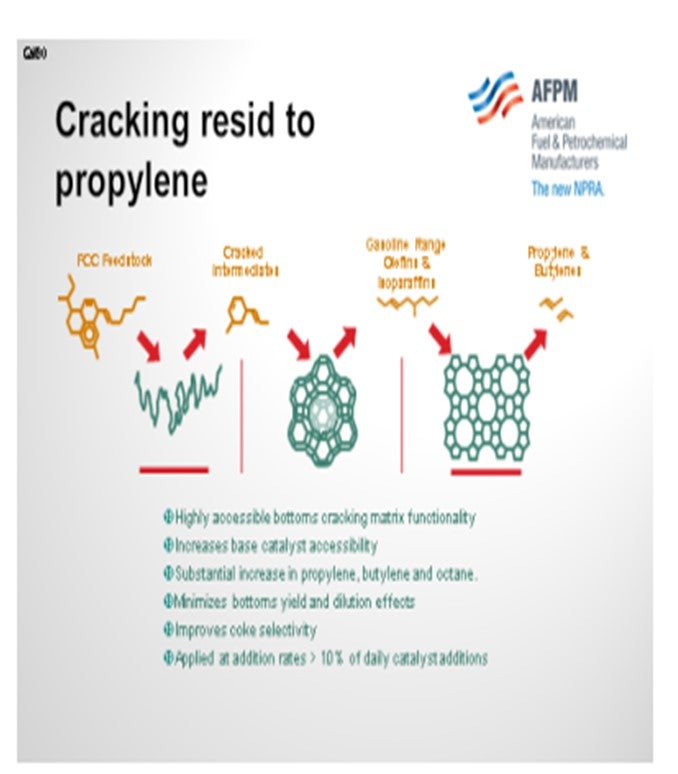

The question was whether ZSM can crack resid. The short answer is no. The long answer is that if you have good catalyst component systems, matrix components, and zeolites, you will be able to crack the FCC feedstocks into light cat naphthas. Basically, the olefins of the light cat naphthas can crack into propylene. The effects we saw that helped resid units make more propylene were using a high accessibility catalyst and preventing dilution effects, as well as the list shown on the slide.

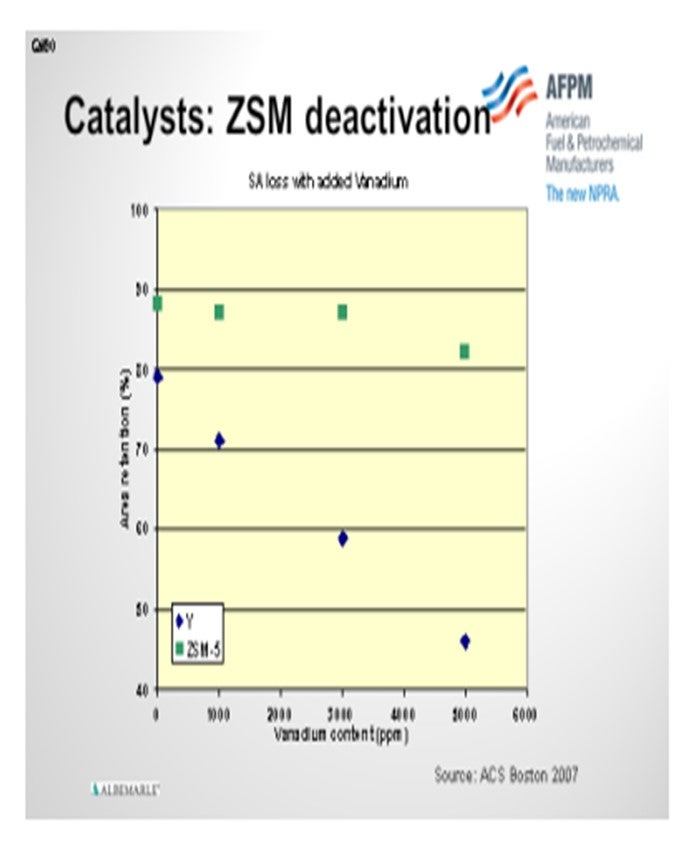

ZSM will deactivate, but much slower than Y-type zeolites. ZSM-5 has a far higher silica-to-alumina ratio and dealuminates less than Y zeolites. In an ACS (American Chemical Society) Boston 2007 report, we revealed that ZSM is less affected by hydrothermal steam conditions and metals effects from vanadium, in particular. You see this result on the slide. Shown on the Y axis is surface area retention. This particular test used pure component systems; so when you see the ZSM, you know that it represents a pure ZSM in Y. It is also a pure Y zeolite. The zero point is just steaming at 800°C; that is, 100% steam for five hours. The graph shows that at those conditions, the ZSM has maintained 88% of its original surface area, while U.S. Y-type maintained only 79%. As we increased the vanadium levels on the catalyst, there was a decrease in retention for both the ZSM and the Y zeolite. However, you can also see a bigger decrease in the Y-type zeolites with increased vanadium.

LALL (UOP, A Honeywell Company)

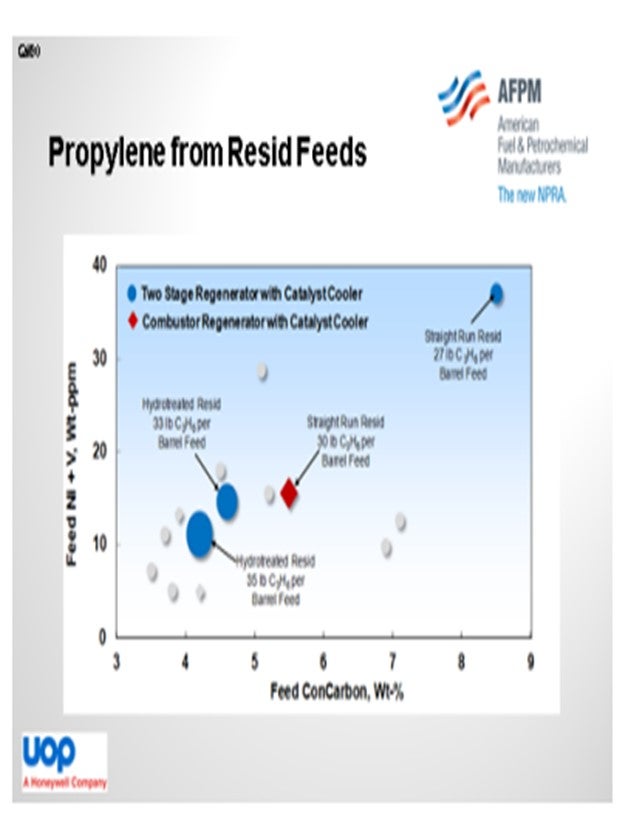

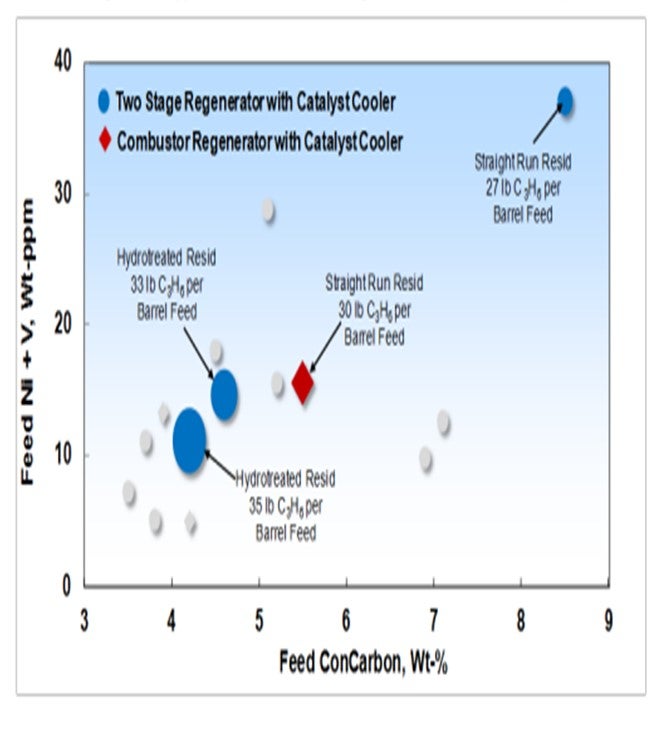

UOP’s resid FCC technology, coupled with FCC catalyst systems incorporating the use of ZSM-5 additive, has been successful producing propylene at levels as high as 10 wt% to 11 wt% on fresh feed. The slide shows a typical propylene yield from various UOP resid FCC units operated in propylene mode for varying total feed metals versus feed Conradson carbon for both two-stage regenerators and high efficiency combustor-style regenerators.

We have several commercial units. A couple of them are operating above 4 wt% Conradson carbon residue, and a few operate above 7 wt% Conradson carbon residue. Optimization of the resid FCC operation and ZSM-5 addition can overcome the challenges associated with processing resid feedstocks. The slide shows a consistent correlation between propylene production and feedstock quality.

While it is recognized that vanadium has a strong deactivating effect on Y zeolite, its deactivating effect on ZSM-5 has not been as widely recognized or documented. Much of the current understanding of the effect of vanadium on ZSM-5 has been derived from deactivation indices for Y-zeolite. Measurements of ZSM-5 surface area and poor volume retention remain fairly unchanged even after a simulated deactivation by deposition of vanadium at high levels, as high as 5,000 ppm. Additionally, standard acidity measurements do not appear to be strongly affected by the presence of vanadium on the catalyst surface either. It has been hypothesized that due to the lack of property shifts, the presence of vanadium has minimum impact on ZSM-5 deactivation; but due to uncertainty expressed by the industry, this theory is under investigation.

JOSEPH McLEAN (BASF Catalysts LLC)

I have a few comments. First, heavier feed units tend to turn over the inventories faster. We tend to think of ZSM-5 levels in terms of percentage of fresh catalyst; but if you are turning the inventory of the catalyst over faster, then you are adding more ZSM-5 and turning it over faster as well. Whenever you are trying to compare heavy feeds versus light feeds, you need to keep that effect in mind. We recently had an opportunity with one customer who went from a hydrotreated gas oil and essentially very, very low metals on the e-cat at 100 ppm levels to 3,000 ppm nickel with some strange feed that they had received over a period of just a few weeks. So we saw how that changed in a very rapid response. There were some changes in the propylene yield on the unit, but they were due to better effects of the feed. When we looked at the e-cat selectivity with standard testing, there was no change in the propylene selectivity for that kind of a rapid change. We did analyze the e-cat microscopically; and just by looking for association of nickel with phosphorous, we basically did not see any change. Nickel does not seem to affect ZSM-5 particles, as you would expect, because the nickel cracks from the asphaltenes and basically stays where it cracked. Vanadiums are a little more difficult to analyze because of their mobility. But in this case, there was not a lot of vanadium, just high nickel.

DR. PAUL DIDDAMS (Johnson Matthey Intercat) I agree with what Joe said. I also have a comment about Cliff’s chart where he showed the surface area retention versus steaming. That is basically what we see, too. What the chart does not take into account is the dealumination of the ZSM-5. You are showing around a 10% reduction relative in activity, which is less than what I have seen.

PATRICK BULLEN (UOP, A Honeywell Company)

My question is related to ZSM-5. It is a little bit different and off-topic. Has anyone noticed a trend in the increased use of ZSM-5 with an increase in acetone in the C4 streams coming off the unit?

BROOKS (BP Refining)

I would not say no, but we have not looked at it.

PATRICK BULLEN (UOP, A Honeywell Company)

So, you think it is a secondary reaction that might be caused by the ZSM-5?

PIMENTEL (CITGO Petroleum Corporation)

We do measure oxygenates in the LPG in the BBs. But in our case, they are mostly related to oxygenates in the feed or some oxygen coming in with the aerated catalyst flow back to our reactor. So, you will think that the incremental production of olefins, because the ZSM-5, would actually reduce the concentration of oxygenates.

DR. PAUL DIDDAMS (Johnson Matthey Intercat) I am sure that acetone is measured quite widely. As catalyst suppliers, we do not tend to get it reported to us very often. ZSM-5 has been around in FCC for over 20 years. So, if there had been a strong relationship between acetone and ZSM-5 usage, it would probably have come to our attention by now; but it has not, and I do not think anyone here is jumping up and saying, “Yes, I have seen that.”

AVERY (Albemarle Corporation)

ZSM-5 usage is widely used in FCCU operations to maximize propylene yields. ZSM-5 usage is just as popular in resid as it is with gas oil operations. High propylene yield units include feeds greater than 6 wt% CCR (continuous catalyst regeneration) and e-cat metals exceeding 10,000 wppm Ni + V. The small pored ZSM-5 is unable to directly crack the large pore resid molecules. To maximize propylene, refiners must optimize their operating conditions, unit design, and FCC catalyst systems to first maximize light naphtha olefins. Catalyst systems with low hydrogen transfer and high accessibility work the best for maximizing light naphtha olefins. ZSM-5 additives or other proprietary technologies will then crack these abundant naphtha olefins to yield high levels of propylene.

ZSM-5 will deactivate, although at a slower rate than Y-type zeolites. ZSM-5 has a far higher SAR (silica to alumina ratio) and dealuminates less than Y-type zeolites. An ACS Boston 2007 report reveals that ZSM-5 is less affected by hydrothermal (steam) conditions and metals (vanadium) contamination than traditional Y or U.S.Y zeolites.

LALL (UOP, A Honeywell Company)

UOP Resid FCC technology, coupled with FCC catalyst systems incorporating use of ZSM-5 additive, have been successful at producing propylene at levels as high as 10 wt% to 11 wt% propylene on fresh feed. The figure below provides a broad summary of the typical propylene yield from various UOP RFCC units operating in propylene mode at various total feed metals on equilibrium catalyst versus feed Conradson carbon content.

Optimization of UOP RFCC technology operation and ZSM-5 addition can overcome the challenges associated with processing resid feedstocks. Figure 1 shows the consistent correlation between propylene production and feedstock quality.

While it is widely recognized that vanadium has a strong deactivating effect on the Y-zeolite, its deactivating effect on the ZSM-5 has not been widely recognized nor documented. Much of the current understanding of the vanadium effect on ZSM-5 has been derived from the deactivation indices for the Y-zeolite. Measurements of ZSM-5 surface area and pore volume retention remain fairly unchanged even after simulated deactivation by deposition of vanadium at levels as high as 5,000 wppm. Additionally, standard Lewis & Bronsted acidity measurements do not appear to be strongly affected by the presence of vanadium on the catalyst surface either. It has been theorized that due to a lack of property shifts, that vanadium presence has a minimal impact on ZSM-5 deactivation; but due to uncertainty expressed by the industry, this theory is under investigation.

ROSANN SCHILLER (Grace Catalysts Technologies)

Yes, ZSM-5 additives are being used successfully, for example, in Asia and the Middle East, where the predominant FCC feedstock for maximum propylene FCC units is heavy, high metals resid. We have developed our AP-PMC and PROTAGON catalyst platforms to address the demands of these units. IN addition, there are numerous resid applications around the world that target moderate propylene increases in which ZSM-5 additives are used. Regardless of the product to be maximized, the foundation for a superior resid cracking catalyst is coke-selectivity and bottoms cracking activity. These are the primary considerations in the design of these catalyst families. Grace’s ZSM-5 additives such as OlefinsMax, OlefinsUltra, and OlefinsUltra-HZ are being used successfully in many resid units, together with AP-PMC, Protagon, Impact, Nektor-ULCC, and ResidUltra.

Industry experience indicates that high levels of Ni + V do not affect the performance of Grace’s ZSM-5 additives. Our customers have operated successfully with a combined Ni +V of up to 13,500 ppm. On the other hand, feed properties have a significant influence on product yields, including propylene selectivity.

Fundamental research has shown that ZSM-5 additives do not accumulate metals at the same rate as base cracking catalysts. This, in part, helps to explain why metals effects on ZSM-5 are not easily observed in commercial operation.

HARVEY MCQUISTON (Technip Stone & Webster)

The use of ZSM-5 has been well demonstrated in Resid FCCs. Due to the small pore size and the shape-selective nature of ZSM-5, the effect of Ni and V is much less than it is on the base FCC catalyst. The main effect of Ni and V is that Resid FCCs normally require a higher catalyst makeup rate (and withdrawal rate) to control metals at an acceptable level and therefore the ZSM-5 makeup rate is higher because it gets flushed out with the base FCC catalyst. The two-stage regeneration technique utilized in the Technip Stone & Webster Resid FCC design provides more catalyst tolerance to Ni and V and therefore reduces makeup cost of both base FCC catalyst and ZSM-5.