Question 86: What test method (e.g., ASTM D86, D1160, or D2887) do you currently use to determine the distillation of FCC gasolines, cycle oils, and fractionator bottoms?

AVERY (Albemarle Corporation)

I put distillation methods into two different categories. One is simple distillation or acts of distillation, which is either a D86 or D1160. D86 is at atmospheric conditions; the D1160 would be at a vacuum. More people are switching to simulated distillations or using a GC (gas chromatography) to do that. The most common number is a D2887. There are other numbers, depending on if there is oxygen in the stream, if you want light ends, or if you are really focusing on heavy ends.

The GC methods are becoming more common because they require a smaller sample size and because an operator can do far more methods that way. As an example, in our laboratories, we used the D1160s but have now switched to D2887 for most types of streams. We also use high temperature simulated distillation for some heavy resid types. We could run about 12 in a day if we did a D1160. Since we switched to simulated distillation with GC methods, one operator can do a hundred samples in a day by himself. So, we saved quite a bit a time when we switched to using GC methods.

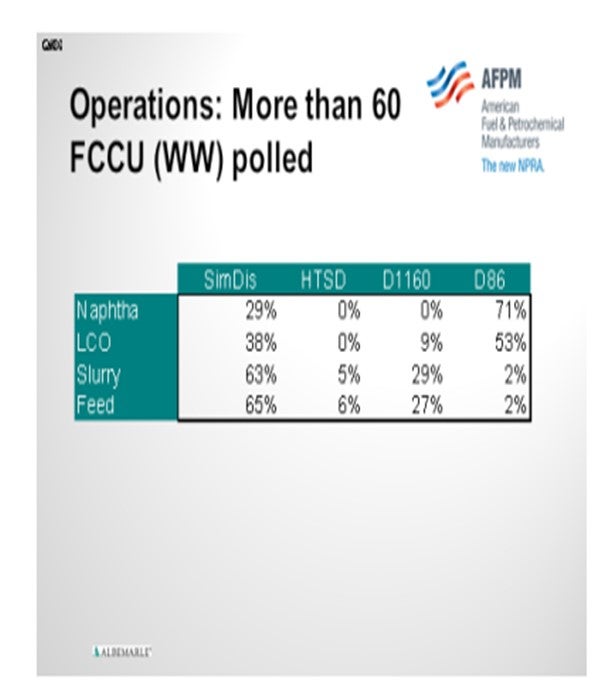

I took a survey of over 60 FCC units worldwide. The slide shows a list of the naphtha streams, LCO streams, and slurry in feed. As you can see, D86 is more commonly used for the light boiling point ranges. This survey also ranged from 2000 to 2012. If I did a poll through that period of time, the ones close to 2000 used more of the simple distillations, like a D86, D1160; most common are all of the GC methods. More people are using what I listed as HTSD, which is high temperature simulated distillation. HTSD is a GC method that helps you measure the really heavy components that boil up to 1350°F.

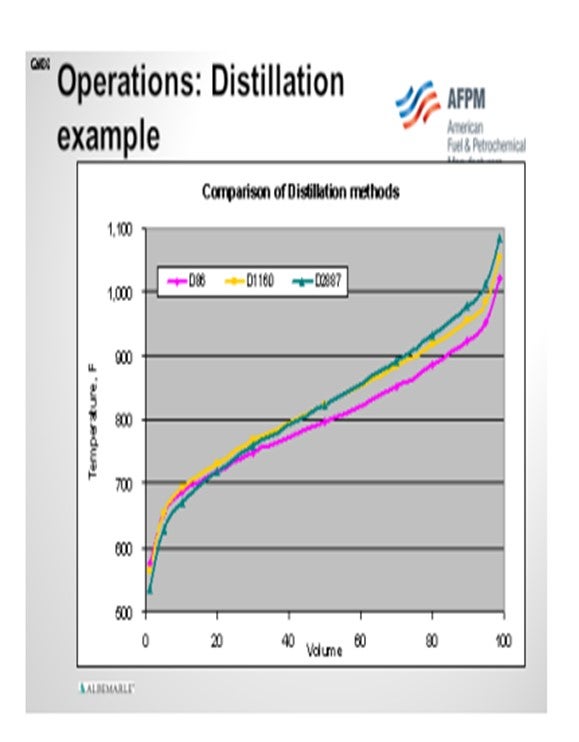

I spoke with our R&D (Research & Development) guys and asked them to create a graph showing some examples of a D86, D1160, and simulated distillation. The yellow stream represents D1160 as the standard done in a vacuum. If you run a D86, you are going to see more thermal decomposition occurring above 650ºF. I forgot to mention that a D86 is generally not used for heavier boiling points; because somewhere around 600°F to 650°F, you will see thermal decomposition. You can see the D86 represented by the pink line. Once it gets into a higher temperature, about 700ºF, it will have a different slope due. When you start going to GC methods like the D2887, you will see larger tails. So, if you look at D1160 and at the simulated D2887, you will see a larger tail here in green and also a larger tail on the backend.

KEVIN PROOPS (Solomon Associates)

To the panel members in operating companies, as you have changed your distillation methods over time, have you gone back and updated all of your unit monitoring calculations to now calculate standard conversion at a 430 cutpoint using your new methods, or did you ignore the change in distillation method?

AVERY (Albemarle Corporation)

Data from refineries is often generated by using kinetic modeling. Within that process of collecting data, they will have inputs for the method. Those systems will automatically take care of the corrections.

BROOKS (BP Refining)

Our sites use models similar to those Cliff just mentioned.

SCHOEPE (Phillips 66)

I second that for Phillips 66.

AVERY (Albemarle Corporation)

Basically, distillation methods are in two categories: simple batch distillations (D86/D1160), and simulated distillations by gas chromatography. Initially refiners used ASTM D86 to determine oil boiling points (BP). The D86 simple batch distillation, or low efficiency distillation, is performed at atmospheric conditions. Decomposition or thermal cracking of the material can occur at temperatures greater than 650°F (344°C). Due to this high temperature decomposition, the ASTM D1160 method was developed. The D1160 is performed at reduced pressures [typically around 10 mm Hg (millimeters of mercury)]. At this pressure, oil fractions up to 1,000°F (538°C) can be accurately analyzed.

Simulated distillations (SimDists) are performed by GC. The most popular method is ASTM D2887. D2887 determines the boiling point distribution by injecting the oil sample into a GC that separates the hydrocarbons in a boiling point order. The retention time in the GC is related to the BP through a calibration curve. Recently, newer GC methods have been used. High temperature simulated distillation (HTSD) can accurately measure BPs greater than 1,000°F (538°C).

Simulated distillations save a significant amount of time, utilize less manpower, and require a smaller sample size: all advantages over simple distillations. At Albemarle, we run a standard D2887 for lighter BP fractions. For heavier oils such as FCC feed, we utilize a customized HTSD to assure we accurately measure the heaviest BP compounds. Our D1160 capacity was approximately twelve samples/day using one liter of oil and at least one technician. Our D2887 system has a capacity of 100 samples per day using less than one milliliter per sample and one technician.

Data from over sixty FCCUs were reviewed. The data runs from 2000 to 2012 and comes from every WW region. The general observation is that the method analyzed on feed is also performed for the slurry. For naphtha and LCO, many refiners are staying with the D86 method. More recent data and data from larger and/or major oil companies tend to utilize GC methods. Second-generation GC methods (HTSD) are showing up more often.

SCHOEPE (Phillips 66)

All Phillips 66 sites except one use simulated distillation methods for gasoline LCO and slurry distillation. D7096 is used for gasoline, D2887 is used for LCO, and high temperature D7169 or D6352 is used for slurry. One Phillips 66 site still uses D86 for gasoline and LCO.