Question 82: Do you have any experience with the recycle of C4/C5 streams from the FCC gas plant back to the FCC? If so, what was your motivation? What is the system configuration, and what are the key operating parameters?

PIMENTEL (CITGO Petroleum Corporation)

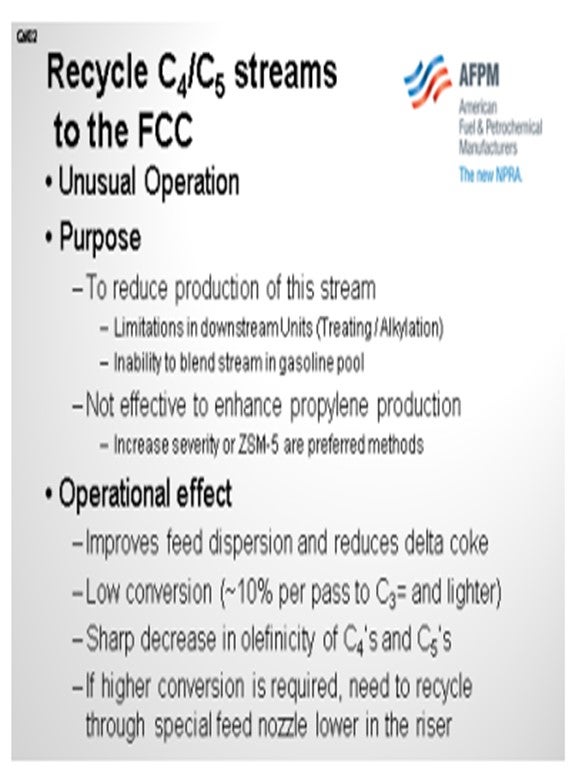

We have some experience recycling BBs (butane-butylenes) from the gas plant back to the FCC reactor, and even some C5s. I will start by saying that this is a very unusual operation. Its sole purpose is actually to reduce the production of the BBs or the C5s due to limitations in downstream units, such as alkylation, treating, or their inability to blend this material into the gasoline pool as a result of RVP (Reid vapor pressure) limitations. So the purpose was actually to destroy some of these materials rather than produce propylene. This is not a good alternative to increasing your propylene production. Better options are, of course, to use ZSM-5 additive or increase severity.

Our experience is with recycling BBs, along with gas oil, into the feed nozzles. We found that feed dispersion improved and delta coke reduced because of the cooling effect of BBs vaporizing in the riser. We found a very low conversion per pass – 10% or less – to propylene or lighter. However, we did find a sharp decrease in the olefinicity of the C4s and C5s. In our refinery, we typically have about 55% olefins in the BBs and the 45% iso- and normal butane. After a while, these percentages were the opposite with this operation. We soon found more paraffins than olefins, suggesting that only the olefins would react under this environment; the paraffins will remain unreactive.

If you require higher conversion of this material, we recommend that you install a special feed nozzle below your gas oil nozzles in the riser. That way, you will probably achieve a reactor mixed temperature over 1200ºF, which is required in order to crack light paraffins.

LALL (UOP, A Honeywell Company)

The practice of recycling heavy C5-bearing streams, such as LCN (light coker naphtha), has long been practiced by refiners with the general intent of achieving incremental gains and valuable C3 and C4 olefins. Some refiners have also been known to route or dispose of very high sulfur-bearing naphtha, such as coker naphtha, where no alternative deposition exists at the refinery. UOP is currently investigating conventional and non-conventional solutions, including recycle streams for maximizing propylene.

SUBHASH SINGHAL (Kuwait National Petroleum Company)

Does the recycle of C4/C5 streams to FCC impact the fresh feed to the unit? Does it impact the total feed to the unit? For instance, if you recycle any stream, does the feed to the unit come down?

PIMENTEL (CITGO Petroleum Corporation)

It could, although it was not our experience. We were not limited in the hydraulics of the feed system, but it will depend on where you inject the BBs. In our refinery, we injected the BBs upstream of the feed heater and downstream of some of the heat exchangers. So, you will have vaporization there. Can you take that additional ΔP (delta P; differential pressure) in your heater, or do you have a fired heater for your feed? Those are the kinds of questions you have to ask. If you have a marginal pressure drop or hydraulic limitations, then yes, it will surely limit your capacity.

LALL (UOP, A Honeywell Company)

To add to Sergio’s comments, look at your cyclone velocities. Clearly, putting in some light material and cracking will increase the velocity in the cyclones; so be aware of that.

DR. PAUL DIDDAMS (Johnson Matthey Intercat)

Your observation about the C4/C5 olefinicity decreases is not likely to be due to olefin cracking and paraffins being preserved. C4 and C5 olefins are not cracked via a carbenium ion mechanism in the FCC because the C2 carbenium ion intermediate required in the mechanism is unstable; therefore, the reaction does not occur catalytically. It is much more likely that your olefins are subject to hydrogen transfer that saturates them through to the paraffins. However, if you increase severity in the FCC by getting the reactor temperature above about 565°C, and if you use a lot of ZSM-5, then you will get into a regime where the C4/C5 olefins can oligomerize temporarily and then re-crack to lighter olefins. But this really only happens under quite severe conditions with high levels of ZSM-5 present.

DILIP DHARIA (Technip Stone & Webster Process Technology)

I agree with Dr. Diddams’ comment. We have seen, and have already said in our Answer Book response, that recycling C4 and LCN results in the benefits of increased propylene in our DCC (deep catalytic cracking) units where severity is high; for instance, when the temperature is at 565ºC and a lot of ZSM-5 additives are present. We suspect that the oligomerization which follows happens prior to cracking, which increases the propylene yield.

JOSEPH McLEAN (BASF Catalysts LLC)

Again, talking about slurry recycling in the last question and LCN recycle here, no one mentioned the heat balance. If you are air blower-constrained, then any recycle you put back in the riser is an extra load system. So if you are air blower-limited and increase the recycle of any kind, you may need to back out fresh feed or change something else to be able to live with that change. Always keep the heat balance effects of these things in mind. You can talk about yield effects, crackability, and olefinicity changes. These situations are all true, but also keep in mind that you must have some air to make these reactions happen.

PIMENTEL (CITGO Petroleum Corporation)

We have limited experience with the recycle of light hydrocarbons (C4/C5) from the gas plant back to the FCC. The main reason to try this operation should be limitations in downstream units (alkylation or treating) or the inability to blend these streams in the gasoline pool. If the goal is to boost propylene production, the preferred option should be to increase FCC severity or the use of ZSM-5 additive. In our experience, the C4/C5 stream was recycled to the riser in combination with the gas oil to the feed nozzles. As expected, there is an increase in cat/oil due to the cooling effect of vaporizing the light materials and some improvement in feed atomization. We found a relatively low conversion per pass (about 10% conversion to C3s and lighter) and a sharp decrease in the olefinicity of the C4/C5 cut (from 55% to 45%), which suggests that mostly the olefins react under these conditions. In order to achieve higher conversion or crack light paraffins, a separate feed nozzle located below the gas oil injection in the riser is required.

LALL (UOP, A Honeywell Company)

The practice of recycling heavy C5 bearing streams, such as LCN, has been practiced by refiners with the general intent of achieving incremental gains in valuable C3 and C4 olefins. Some refiners have also been known to route or dispose of very high sulfur bearing naphtha where no alternative disposition, such as coker naphtha, exists at the refinery.

DILIP DHARIA (Technip Stone & Webster Process Technology)

Technip Stone &Webster has licensed a high severity deep catalytic cracking unit in the Middle East that recycles C4s and LCN to the riser with the main objective of increasing propylene yield. It should be noted that only the olefinic portion of these streams are reactive and the increase in propylene yield was confirmed.