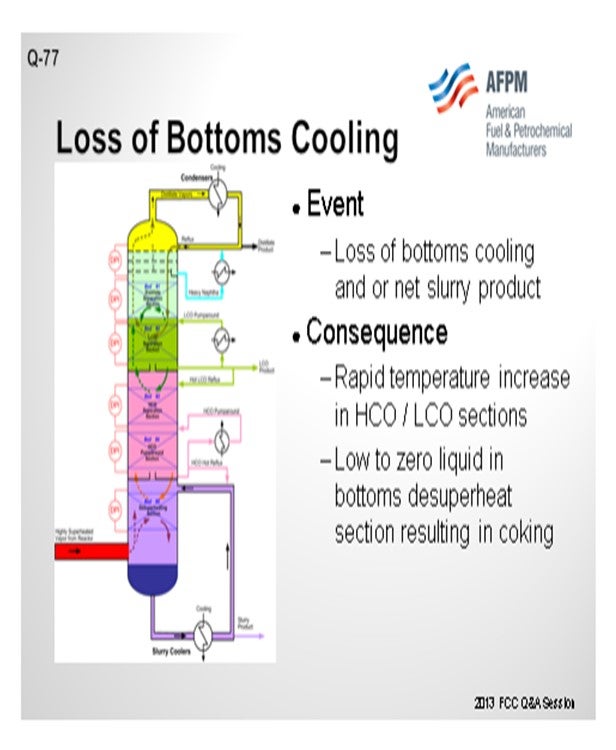

Question 77: What are the consequences associated with continuing to operate the FCC without main fractionator bottoms cooling circulation?

LARSON (KBC Advanced Technologies, Inc.)

We considered this question as three parts: What is the action to follow in the event of a loss of bottoms’ cooling? What is the consequence if you lose the net slurry product? What are the operational possibilities if you have a well-planned outage of the slurry circuit?

In situations one and two where you have lost circulation or you have lost the net bottoms’ product in the system here, we expect that you would shut down the unit consistent with your licensure’s emergency shutdown procedures. The consequence of losing the bottom circuit is that all this heat will transfer up the tower; however, your other pumparound circuits will be insufficient to handle the step change in heat removal. One of the consequences could also be that if the temperature continues to increase, you will, in fact, coke off the bottom of the tower.

Part Three of the Question: There are the rare instances where your specific configuration will allow you a planned outage. I have a colleague whose equipment has this capability because of its specific configuration. This client could take the bottom circuit offline after reducing feed rate and taking a number of actions to make sure there is enough heat removal up the tower to be able to service the pumparound pump. That is a unique situation, but it is one that may exist in the facility.

MEL LARSON (KBC Advanced Technologies, Inc.)

This question is considered in three parts:

1) What is the action to follow in the event of a loss of bottoms (slurry) cooling circulation? 2) What is the consequence from a loss in net bottoms product withdrawal? 3) Discuss operating with a well-planned outage of bottoms circulation.

In situation one or two where there is an immediate loss of bottoms cooling and/or net bottoms product removal, the unit should be shut down in accordance with licensor or company emergency shutdown procedures. The loss of bottoms cooling will result in excessive heat moving up the tower which will exceed the ability of the intermediate pumparound or reflux systems to adequately cool the column for continuous operations. Depending upon the tower design, temperature excursions beyond the design may exceed metallurgical stress allowances. The consequence of immediate loss of cooling and/or net product with the attempt of continuous operation likely results in the bottom of the FCC main column coking rapidly.

Part 3 considers the limited possibility that in a planned manner, the combination of unit feed rate reduction and tower heat balance adjustments may allow for the bottoms system to be taken out of service. A rigorous review of the specifics on the tower heat balance and hydraulics with each pumparound system would be required. Product must be removed from the bottom of the column in any case.

CHRIS STEVES (Norton Engineering)

Each FCC main fractionator is designed differently; but in general, it will not be possible to run for very long without the bottom pumparound. In many cases, this pumparound stream provides up to 50% of the total heat removal required for the tower; so operating without it would require a significant rate reduction. Additionally, the bottom pumparound is used to desuperheat the reactor vapors as they enter the main fractionator. Operation without the bottom pumparound in service will significantly raise temperatures in the main fractionator and could lead to mechanical damage or coke formation in the HCO (heavy cycle oil) or LCO (light cycle oil) sections. With the loss of lower pumparound, it would be expected that catalyst fines will migrate into the HCO and LCO sections of the tower in higher concentrations than normally seen, which could lead to plugging issues.

JACK WILCOX (Albemarle Corporation)

The main column bottoms circulation circuit removes the largest portion of heat from the reactor effluent. If this circulation is lost for more than a few minutes, the unit must be shut down; otherwise, the following will occur:

- The bottoms liquid level will increase flooding the reactor effluent vapor line inlet line to the main column.

- The bottoms liquid residence time will increase, leading to increased coke formation.

- The internal temperature will increase, potentially damaging the column internals.

- As the column bottoms liquid level increases, catalyst fines suspended in this material will be carried up the tower.