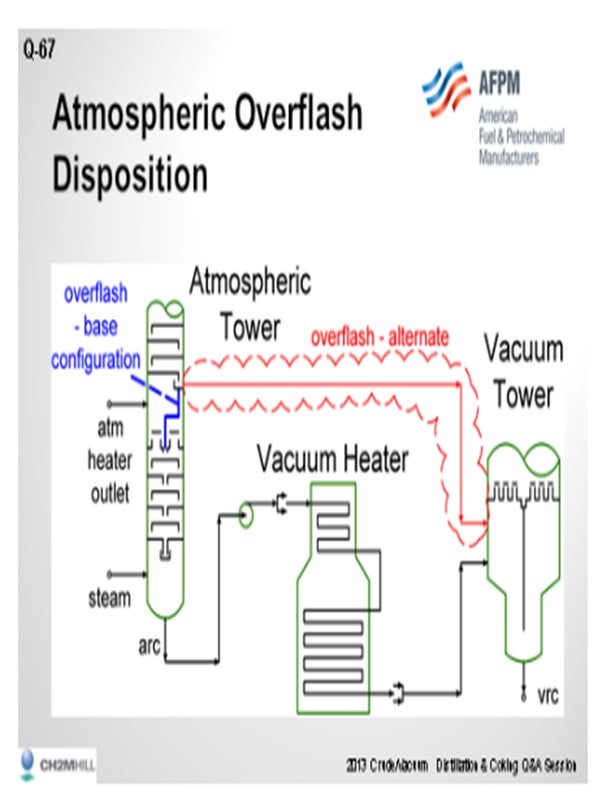

Question 67: When heat input is limited at the vacuum heater, what are the issues with bypassing crude tower over-flash around this heater?

SLOLEY (CH2M Hill)

For this answer, I am going to define crude tower over-flash as liquid collected on a collector tray above the flash zone at the atmospheric crude column. This may be either a total collector tray or some form of active tray. This liquid contains a mixture of entrainment from the flash zone and distillate from the wash section. The normal disposition is to send the liquid inside the tower down to the stripping section. The lighter end of the material is stripped and recovered in the atmospheric tower and the heavier material ends up as atmospheric tower bottoms. So the overflash stream is distinct from the atmospheric tower bottoms. It has not been stripped. It contains light material often down into the kerosene boiling range. Depending on the vacuum tower configuration, the light material can significantly load the vacuum system.

Dry vacuum towers (that is, vacuum towers with no pre-condenser in front of the ejector) tend to have small vacuum systems. The additional load from the unstripped material can significantly raise the vacuum ejector suction pressure. The vacuum towers with large ejectors or with pre-condensers tend to be more resistant to small changes in the load to the light material to the ejector. Conceptually, sending this stream directly to the vacuum tower has somewhat the same effects as damage to the stripping tray section. The query to the person who asked the question would be: Why not just bypass some of the atmospheric tower bottom if you are going to do this? Really, it will have the same effects on unloading the vacuum heater duty and will have a smaller effect on the vacuum system.

Now if the vacuum system can handle a light material, bypassing does gain you some yield on the gas oil in that stream. Nevertheless, you can get flashed on quenching if you mix that material with the vacuum heater outlet. The Best Practice would be to send this to the vacuum tower and let it flash without mixing with the material coming from the vacuum heater.

One other observation: In the case with a packed atmospheric tower wash section that operates properly, the total over-flash rate is very low compared to the crude. The distillate content is also low. Except for the vacuum system loading, the effect of bypassing the over-flash would be so small it would be nearly unnoticeable.

Trayed atmospheric towers require much higher liquid rates to work properly, so the over-flash rates may be much higher and give you a noticeable yield change with different over-flash dispositions. The atmospheric tower configuration will also affect the benefit of the changes seen. Over-flash from the atmospheric tower, with diesel as the lowest product, will have more light material, and that will cause a higher load change on the vacuum system.