Question 57: Do your CDUs/VDUs (crude distillation units/vacuum distillation units) employ automatic trip systems to mitigate tower level overfills? What is considered the Best Practice for high level detection and response?

BASHAM (Marathon Petroleum Corporation)

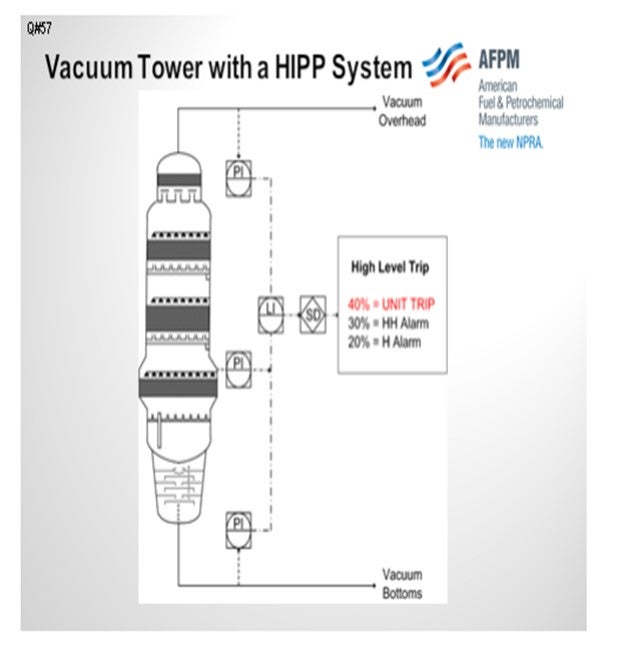

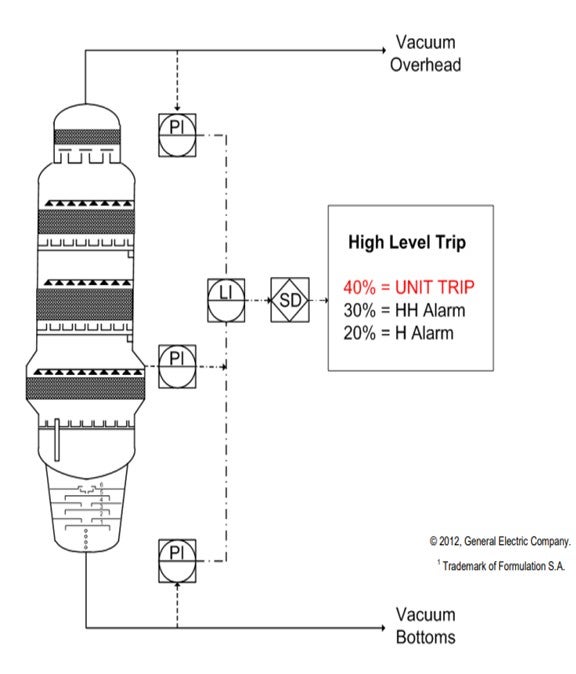

We do have a High Integrity Pressure Protection System, or a HIPPS, that is going to be installed on a crude unit vacuum tower at our Detroit refinery this fall. We are installing it in order to prevent a scenario where the weight of the liquid would overcome the low-bearing capability of the foundation. If you take a look at the slide, you will see a schematic of the HIPP system that we are installing on the vacuum tower. Essentially what you have is pressure indication across the tower. That pressure indication is then converted to level, and then the level indication is connected to the shutdown system. In this case, a 40% level on the tower would trigger a unit shutdown. A less expensive solution would be to install a pressure transmitter on the suction of the tower bottoms pumps, and then use this to determine when the level is above the tower bottoms level transmitters.

We have also had numerous instances during startups where we had high levels in crude atmospheric towers, crude vacuum towers, or coke re-fractionators which caused aborted startups or even tower internal damage. We have also seen tower overfill scenarios in distillate and gas oil hydrotreater stripper towers. In the case of the gas oil hydrotreater or stripper tower, we have actually filled to the point where we have gone out the top of the tower. The temperature of the hydrocarbon was sufficient enough to cause damage to the overhead air cooler tubes.

TRAN (Houston Refining LP)

We do not employ automatic trip systems. Our Best Practice is to use a combination of nuclear and differential pressure level indication with high level alarms. The operator’s response time on an emergency alarm is less than five minutes. In a high priority, the response time is less than 30 minutes.

DARYL HANSON (Valero Energy Corporation)

Kevin, I have two quick questions about your diagram. First, are there any special issues during startup that worry you about with cold ATB (atmospheric tower bottoms) coming into the tower? And if so, how do your account for those issues?

BASHAM (Marathon Petroleum Corporation)

The shutdown system level trip points were conservatively set based on liquid gravities that ranged from hot ATB to water, so cold ATB is included in this range.

DARYL HANSON (Valero Energy Corporation)

The second question is if you are going to pull all of the feed out of the unit trip, does that mean that you are going to shut the crude control valve if the level gets too high? BASHAM (Marathon Petroleum Corporation) No, this system only trips the ATB pumps and emergency isolation valves (EIVs), vacuum tower pumparound pumps, and waterwash pumps.

KEVIN PROOPS (Solomon Associates)

Sorry to pick on you, Kevin, but I have two more questions. One is: Do you know if you are going with two-out-of-three voting on those, or are they just the single transmitter?

BASHAM (Marathon Petroleum Corporation)

This system has two-out-of-two voting.

KEVIN PROOPS (Solomon Associates)

I would also suggest that if you have not already thought about it, you might consider conditioning a signal to avoid tripping it on an instantaneous signal. The level changes slowly, so it takes a while for the signal to trigger a shutdown.

ANDREW SLOLEY (CH2MHILL)

Are you incorporating any elements into the trip system to protect the upstream heater in the case of a sudden loss of heat when the trip cuts the feed out to the vacuum column?

BASHAM (Marathon Petroleum Corporation)

No, this system is only guarded against an overfill scenario.

BASHAM (Marathon Petroleum Corporation)

We have a High Integrity Pressure Protection (HIPP) system going on the crude unit vacuum tower at Detroit this fall. It is being installed to prevent a scenario where the weight of liquid would overcome the foundation’s load bearing capability. No other towers at Marathon Petroleum Company have this type of automatic trip system installed. A less expensive solution is to install a pressure transmitter on the tower bottoms pump suction and use this to determine when the level is above the normal tower bottoms level transmitters. We have had numerous instances during startups where a high level on atmospheric towers, vacuum towers, and coker fractionators has caused an aborted startup or damage to the tower internals.

We have seen overfills in diesel and gas oil hydrotreater stripper towers where hydrocarbon has overflowed the top. In the case of the gas oil hydrotreater stripper overfill, the overhead air cooler tubes warped due to the elevated temperature.

LEE (BP Products North America)

In two CDUs, we have an automated system to trip feed upon a high crude tower level. In both configurations, the relief valves discharge to the atmosphere and are considered higher risk than units relieving to a flare system. In both instances, furnace firing is cut first, and then feed is cut out on a time delay. Traditional DP level devices work reasonably well for CDU levels. Using a gamma ray level device for vacuum tower levels has also been done successfully.