Question 54: What is the current best practice for number of feed nozzles, angle, and location on coke drums considering the use of slide valves for the bottom unheading device?

Frank Tracy (ConocoPhillips)

There is not a one-size-fits-all answer to this question. However, we believe that an arrangement that closely matches the conventional bottom center upflow arrangement will provide more uniform thermal stresses on the drum and minimize operational impact.

Within ConocoPhillips we have multiple cokers that have retrofitted valve-type unheading devices onto bottom heads and use single side feed entry. These drums have not had any significant operational or mechanical issues resulting from the retrofits to date. We also have one coker, which still has manual bottom unheading, that has had dual side entry for more than fifty years. We have one new coker that is in construction that will utilize dual side feed entry.

One ConocoPhillips Coking Technology Licensee installed valve-type unheading with single-side entry. Upon converting to single side entry, they experienced significant temperature gradients in the drum resulting in drum deflection and a permanent “banana” shape as well as an increase in blow outs. They are converting to dual side entry and early reports are that this has improved their operation back to where they were with original bottom center upflow arrangement.

Because there are so many factors to consider; including feed properties, operating conditions, and drum geometry; we are using CFD modeling to aid in assessing the number, location, and entry angle for feed nozzle(s). CFD modeling in this application is still a work in progress for us, but we believe it is a useful tool. In some cases,

the additional complexity and cost of dual-side feed entry is warranted while in others it is not.

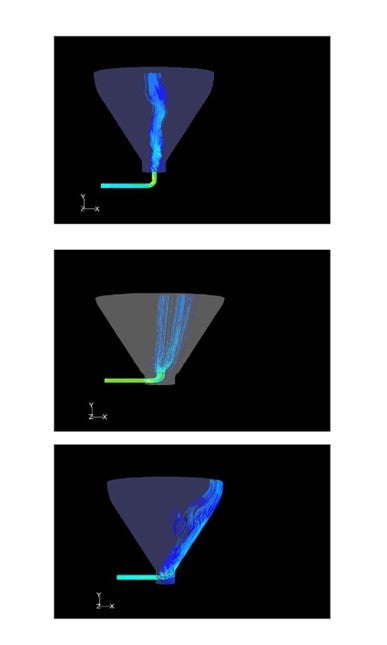

The next three CFD model snapshots illustrate: 1) bottom dead center feed, 2) single side entry for a case where single side entry might be selected, and 3) a case where single side entry as configured might not be recommended. These are different drums with different feeds, conditions, and geometries. ConocoPhillips have CFD modeled several variations around single vs. dual side entry, location of feed, and entry angle.

For dual-side entry there must also be a reliable piping system that is designed to support the nozzle configuration.

ConocoPhillips have licensed four retrofits to dual feed nozzle systems and can provide Licensing assistance in this area.

Finally, DeltaValve have a prototype for a retractable feed device that attempts to simulate bottom dead center feed entry. This is reported to be going into trial sometime in the fall of 2010.

Jim Johnson (Marathon Petroleum)

It is our understanding that industry is leaning toward dual feed nozzles at a 45-degree angle to the bottom cone when installing slide valves. Marathon’s refineries have nine drums with single side entry and have no issues. We did not see our hot drum occurrence increase when we converted from a bottom entry to a side entry when installing the slide valves.

Eberhard Lucke (Commonwealth E&C)

I have seen no major problems with the single inlet nozzle on the side of the drum cone, if designed properly. I also haven’t seen any significant advantage in using multiple feed points around the cone. The single feed injection point should be angled slightly upwards. I like the concept of going back to the old “bottom inlet” flow pattern with the new slide valve designs. I would have to see that one in operation though before I would recommend it.