Question 44: What issues do you consider to establishing a purchased crude oil custody transfer Best Practices from various sources?

SHARPE (Emerson Process Management)

Custody transfer requirements and regulations can differ by world area, by modality, and even by company. Most companies follow API (American Petroleum Institute) standards for the measurement sampling and custody transfer. Generally, there is a pay meter and a check meter. The contract specifies what happens when there is too large of a discrepancy between those two meters. The shipment modality –and by that, I mean truck, railcar, ship, barge, pipelines, etc. –will drive the basic technology in your business processes uses for custody transfers. Large transfers from ships and barges or pipelines will use large capacity lines and often are certified using either a high accuracy flow meter or the tank gauging system as a primary indicator, plus ship hold measurements as the secondary value. A third-party inspector is often engaged to certify the transfer, determine which measurements to use, and record the actual transaction. The inspector will ensure that the specified API standards are followed and that a measurement decision is based on one of three options: the custody transfer meters, if designed, installed, and calibrated properly; the short tank level and the volume, also in accordance with the standards; and finally, the ship measurements.

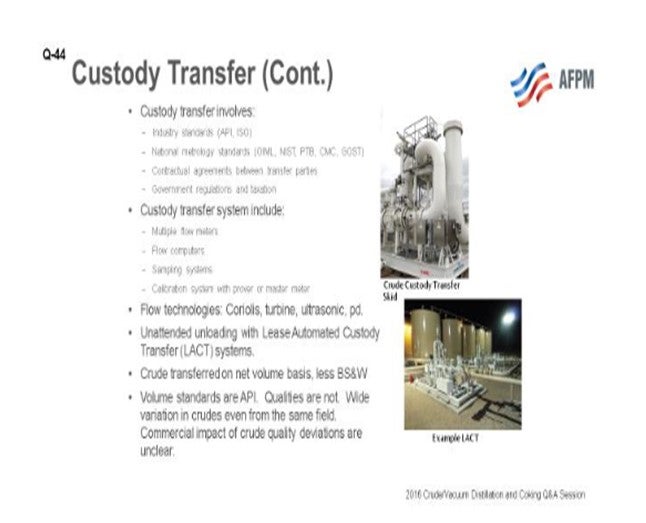

In general, custody transfer involves the industry standards, national metrology standards, contractual agreements between the custody transfer parties, and government regulations and taxation. Custody transfer metering systems must meet requirements set by industry bodies such as API and ISO (International Organization for Standardization). These systems must also meet national metrology standards such as OIML (International Organization of Legal Metrology), the international standard; NIST (National Institute of Standards and Technology) in the United States; PTB (Physikalisch- Technische Bundesanstalt) in Germany; CMC (China Metrology Certification) in China; or GOST (gosudarstvennyy standart; государственный стандарт)in Russia. Custody transfer metering systems are designed and engineered for the application and specifically include multiple flow meters, flow computers, sampling systems, calibration systems, and supporting automation. There are a number of flow technologies that can be used for the purpose of custody transfer. Ultrasonic and Coriolis meters have become the flow meters of choice in crude for the oil and gas industry. These meters have no moving parts and, unlike turbine meters, are not affected by BS&W (base sediment and water) content. Coriolis meters have the added advantage of measuring fluid density so that changes in crude quality can be determined immediately.

When receiving hydrocarbons by truck or rail, the API standards defines a LACT, a leased automated custody transfer system, or metering skid for unattended custody transfers. The LACT system must determine the net volume and quality, provide for fail-safe operation, and be tamper-proof, as well as meet accuracy and dependability requirements as mutually agreed upon between the contracting parties. Most crude transfers are made on a net volume basis, so subtracting out the BS&W to obtain a quantity of merchantable oil is important. It is imperative that a representative sample of the full transfer is obtained as part of the custody transfer process. Sampling crude transfer is usually done with a composite sampler which takes periodic samples from the transfer lines during the time of the transfer. Automatic operation of the sampler provides for uniform collection and representative samples that is analyzed by the lab for various quality measurements.

If crude is transferred from shared pipelines, it creates other challenges. Custody transfers are either metered or measured from tankage. There are API volume measurement standards that require pipeline meter provers, and there is typically no standard for crude quality beyond sulfur and gravity. With shared pipelines, there is mixing between batches and no guarantee that you will receive any specific batch. Volume standards are API; qualities are not. The commercial impact of crude quality is not clear. The industry is now considering checking qualities as part of the custody transfer process, so unconventional crudes, which represent even more challenges because of the composition of the same field, can vary widely with dramatically different API gravities.Some refineries, terminals,and pipeline companies have started using online NIR (near infrared spectroscopy) on the crude coming in for online assays and other critical qualities of the crude received. Currently, there is no way to ensure that purchased crude matches the assay, nor is there commercial recourse if it does not.

MAJI (Essar Oil Limited) I fully agree with what Pete said. The central issue custody is transfer is accurate measurement of quantity at various stages. This included the correct measurement of volume and temperature. Equally important is proper sampling of the crude for density and BS&W purposes so that the mass of the crude oil is properly accounted. Our accounting system is based on the mass of the crude, not the volume.

As a buyer, our main interest is to receive the accurate, correct quantity of crude in our refinery tanks. So wherever available, custody transfer meters with temperature compensation are the best way to proceed. The custody transfer meter with prover in our crude receipt line is doing a good job. Gauging of the tank and water-cutdetermination is not generally very accurate, so we rely on ATG (automatic tank gauging), which is based on radar gauge and multipoint temperature measurements. Manual measurement has its own issues; however, manual measurement has to be done as a contractual obligation.

Electronic ullage temperature and interface (UTI) gauges provide better measurements of the temperature than cup-case measurement. One point I want to mention is that the UTI gauge that has been used by the ship at the load port has to be the same gauge for disport, so there will be less chance for error.

Getting the representative sample is a challenge, as I have already said. Proper sampling, whether at the load port or at disport, depends on many factors; for example, homogeneity, dip hatch design,and adequate settling time. Many times, we are unable to give an adequate settling time because of scheduling constraints. To improve accuracy, we adopt five-level sampling over the traditional three-level sampling, particularly for heavier crudes. The best way is to sample the crude while it is being transferred in a pipeline to the refinery. The sample point has to be in the center line of the pipe and in the vertical section, just after the mixers. Sampling should be on a flow proportional basis, which is doing a well in our refinery.

There are certain other issues. For instance, any error in measurement of BS&W is a big source of loss. We also have issues with heavier crudes. Because the centrifuge method underestimates water, we do not use it. We use the Dean and Stark Water by Distillation method and the ASTM 473 sedimentation test. Karl Fisher is a very accurate method. However, it is very difficult to use as a regular practice because you need a very precise technique to do it. Slackness of the line is another source of loss that must be considered while drafting the contract. For ship shore reconciliation, the generally accepted loss figures are 0.3%, whether at load port or disport, and a transit loss of 0.2%. That is what we accept. Utmost importance has to be given to the Q&Q (Quantity and Quality) clauses while drafting the contract. For our quantity determination process, we follow the Manual of Petroleum Measurement Standards (MPMS), published by API.