Question 4: Is there any experience producing on-specification jet fuel without any sulfur/mercaptan treating, including any form of caustic, from feedstocks produced from ‘tight’ formations? What other jet specifications are adversely impacted by the changed feedstock?

STREIT (KBC Advanced Technologies, Inc.)

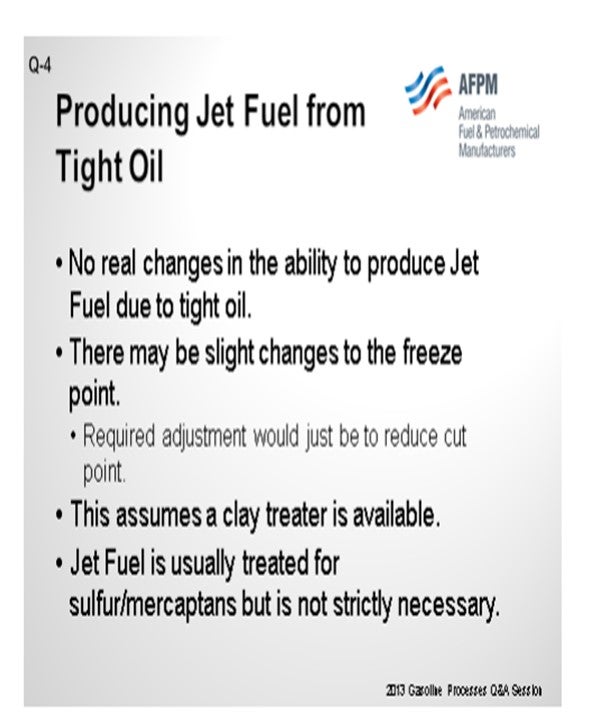

The main idea here is that there is no real change to the way you make jet fuel based on tight oil. There may be slight changes to the freeze point due to the paraffinicity of the tight oil, but that is actually just dependent on the tight oil itself. If that is the case, really all that is required is a cutpoint adjustment in the crude unit to get on-spec on the freeze. You normally have to do some sort of treating through a clay treater in order to get on-spec for JFTOT (Jet Fuel Thermal Oxidation Test) and WSIM (Water Separation Index Modified), but that is not really different with tight oil versus conventional oil. You do not strictly have to treat for sulfur/mercaptan to make jet fuel, but most places like to do some sort of treating as a safety net to make sure that the final product is on-spec, particularly on mercaptan.

GROPP (GE Water & Process Technologies)

In support of what Eric said, we are not aware of anyone consistently producing on-specification jet fuel without some type of processing or treatment to address sulfur compounds including H2S, mercaptans, and thiophenols. Typically, we see refiners using hydrotreating and/or caustic extraction processes to remove these trace contaminants. It only takes a small amount of sulfur in the right form to throw the fuel off specification. Without removing the contaminants, refiners can expect to fail the JFTOT, as well as the Copper Strip Corrosion and Mercaptan or Doctor tests. In addition, without treatment, the fuel may not pass acidity specifications.

TERRY HIGGINS (Hart Energy Research and Consulting)

Regarding the freeze point, I would have thought that freeze point would be more of an issue for people who are running a large amount of Eagle Ford crude. I think you indicated that it was not too much of an issue, just a small cutpoint. Are you familiar with situations where there were large volumes of the tight oils that would have been difficult to make at all, in terms of having a strong impact on that freeze point?

STREIT (KBC Advanced Technologies, Inc.)

I am not personally aware of any particular issue with that situation. It is more of an assumption based on the presumed paraffinicity of the tight oils, which may or may not be true, depending on the specific tight oil we are discussing. I would be very interested to hear if anyone else has any issues with that. R.E. “ED” PALMER (Wood Group Mustang, Inc.) I know that in some designs we are doing on these condensate splitters, where we are making distillates, that distillation cutpoint is limited by the freeze point of the product.

RONALD GROPP (GE Water & Process Technologies)

We are not aware of any finished, on-specification jet fuel produced without some sort of processing to remove sulfur and/or sulfur compounds including H2S (hydrogen sulfide), mercaptans (thiols), and thiophenols. Typically, we see caustic extraction and/or sweetening processes or hydrotreating processes utilized to remove sulfur or change the sulfur compounds to less objectionable forms. If these sulfur contaminants are not addressed, the fuel will likely fail to meet specifications including Thermal Stability (ASTM D3241), Copper Corrosion (ASTM D130), Mercaptan Sulfur (ASTM D3227), and/or Doctor Tests (ASTM D4952-12). In addition, caustic treating or hydroprocessing methods may be required to meet Acidity (ASTM D3242) specifications.

ERIC STREIT (KBC Advanced Technologies, Inc.)

Virtually all jet fuel needs to be processed through a clay treater to ensure that the product meets JFTOT and WSIM specifications. Tight oil processing does not really change this requirement. Although there may be some freeze point differences due to the higher paraffinicity of some tight oils, this can be countered by changing the cutpoint upstream.

Jet fuel can be produced without treating for sulfur or mercaptans due to its high sulfur specification. Some refiners have had success doing this. However, operating with no treatment can be risky. To avoid the risk of producing off-spec jet, many refiners use some type of caustic treating or hydrotreating to ensure that they will not have problems with mercaptans. In any case, tight oil is lower in sulfur content than conventional oil; so, it should only help lower the jet fuel sulfur level. In cases where sulfur may be an issue and hydrotreating is not used, adjustments to upstream cutpoints can be made to marginally reduce sulfur.

Refiners producing jet fuel from tight oils should be aware that the jet fuel final boiling point may need to be decreased due to the freeze point. The economics of processing tight oil should consider this, and linear program cutpoints should be adjusted accordingly. However, it is unlikely that any adjustments to jet fuel final boiling points will influence whether or not to process tight oil.