Question 4: For the isomerization unit, what is your treatment for the streams containing high concentrations of hydrochloric acid (HCl) in the reactor emergency depressurization system?

SUGG (Honeywell UOP)

Currently, UOP does not include treatment of gas from the reactor effluent as it enters the flare header using the emergency depressuring system in our Penex™ or Butamer™ process unit designs. So, depressuring to flare with a highly concentrated hydrogen chloride stream is not to be taken lightly, due to possible corrosion in the flare system because the flare headers are typically wet. Prior to depressuring the reactors to flare, steps should be taken by Operations personnel to minimize the volume of gas to flare. One of these steps is to decrease the reactor section pressure down to that just above the net gas scrubber pressure through the stabilizer scrubber so that the amount of acidic gas being sent to the flare is kept at a minimum.

Further, upon completion of the depressuring step, UOP recommends following the depressuring with the dry gas purge – preferably nitrogen – to sweep the acid gases from the flare system. During or after purging with nitrogen, it is recommended to drain low-point drains in the section of the flare header where acidic-free water can collect and cause corrosion. For Penex and Butamer™ units, experience has shown that extensive corrosion has not occurred in the flare system with the procedures and guidelines provided. UOP is aware of an isolated incident in which a customer reported significant corrosion to its common flare header section. But after changes in the customer’s procedures and changes to the physical layout of their flare header system, the corrosion was no longer reported.

SABITOV (Phillips 66)

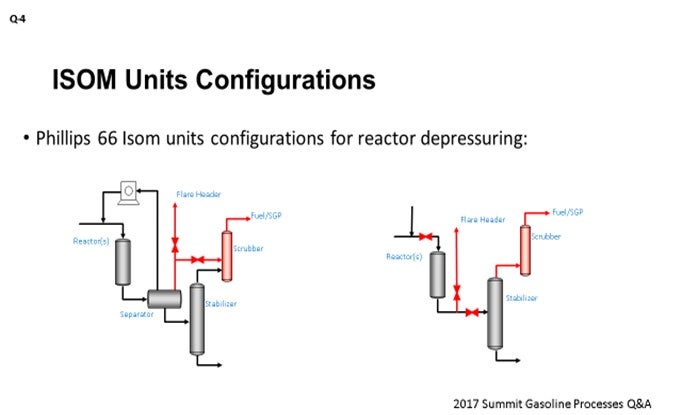

At Phillips, we have two types of the isomerization units, with respect to the hydrogen circuit configuration. The unit shown on the left side of the slide is a recycle gas unit, and the unit on the right is a hydrogen once-through unit. The recycle gas units will depressure the reactors from the separator either through the off-gas scrubber, as shown here on the slide, or they can depressure directly to the flare header. The hydrogen once-through units will depressure through the off-gas scrubber via the stabilizer. They also have an option of depressuring directly to the flare header through the emergency depressuring line at the reactor outlet.

For those units where we use chloride alumina catalyst, you obviously have a very high HCl concentration in the reaction zone. The following considerations would apply: The initial partial reactor depressuring should be performed through the off-gas scrubber down to the pressure of the off-gas destination, which could be set either by the fuel gas header or by a saturated gas plant. This depressuring can be accompanied with the reactor hydrogen sweep. Overall, this step enables neutralization of the peak HCl levels in the scrubber. If full reactor depressure is required due to the continuing runaway situation, then reactors should be depressured to the flare header. In this case, some ingress of the HCl to the flare header might be possible. I should say that those are rare events in our units; and typically, the initial partial reactor depressure is efficient enough to stop a runaway situation. Having said that, we do have one C4 isomerization unit that was built with the provision of the reactor depressure to the dedicated acid relief header, and which is equipped with its own scrubber. Also, if necessary, our refineries can protect their flare headers with the ammonia injection during the isomerization reactor depressuring events.

DUBIN (Axens North America)

We do not have much to add. Those were two very good answers from Patrick and Alex. Axens’ approach is to go through the scrubber system to depressurize directly in there and then into the caustic scrubbing. The one item that we do want to point out is to make sure that the valve systems are protected from an acidic environment so that they are functional when the emergency does arrive.

RAÚL ROMERO (Nalco Energy Services)

My question is about the potential soil deposits that occur when you are neutralizing with ammonia in a header going into the flare system. That is typically trying to keep that as clean as possible to ensure a free passing to the flare.

SABITOV (Phillips 66)

Yes. I guess formation of the ammonium chloride would probably be possible at the right sublimation conditions. We have not really seen any big issues with salt formation. Again, the events of the full depressure are extremely rare, so that does not seem to be presenting any practical problem.

JOCELYN DAGUIO (Honeywell UOP)

Honeywell UOP does not include treatment of gas from the reactor effluent as it enters the flare header when using the emergency depressuring system in our Penex™ and Butamer™ process unit designs.

Depressuring to flare with a highly concentrated HCl stream is not to be taken lightly due to possible corrosion to the flare system because flare headers are typically wet. Just prior to depressuring the reactors to flare, steps should have been taken by Operations personnel. One such step is to decrease the reactor section pressure just slightly above the net gas scrubber pressure through the stabilizer scrubber so that the amount of acidic gas sent directly to the flare is kept at a minimum.

Further, upon completion of the emergency depressuring to flare, UOP recommends following the depressuring with a dry gas purge – preferably dry nitrogen – to remove HCl from the flare system. During or after purging with dry nitrogen, it is recommended to drain low point drains in sections of the flare header where acidic-free water can collect and cause corrosion to the flare header and associated piping.

GEOFFREY DUBIN (Axens North America, Inc.)

Axens recommends that in cases of emergency depressurization of the reactor circuit, the circuit fluid be depressurized into the product stabilizer with the light gases still being treated in the off-gas caustic scrubber. It should be noted that care should be taken to protect safety valves in the reactor circuit to prevent corrosion of the valve and subsequent loss of relief capabilities.