Question 38: Elaborate on the relative value of the various distillate feed streams in a refinery (i.e., straight-run diesel, light atmospheric gas oil, light vacuum gas oil, light cycle oil, coker distillate, kerosene, coker naphtha, heavy cat naphtha, and other) when considering maximum saturation and volume swell in high-pressure ULSD service.

VICHAILAK (Marathon Petroleum Corporation)

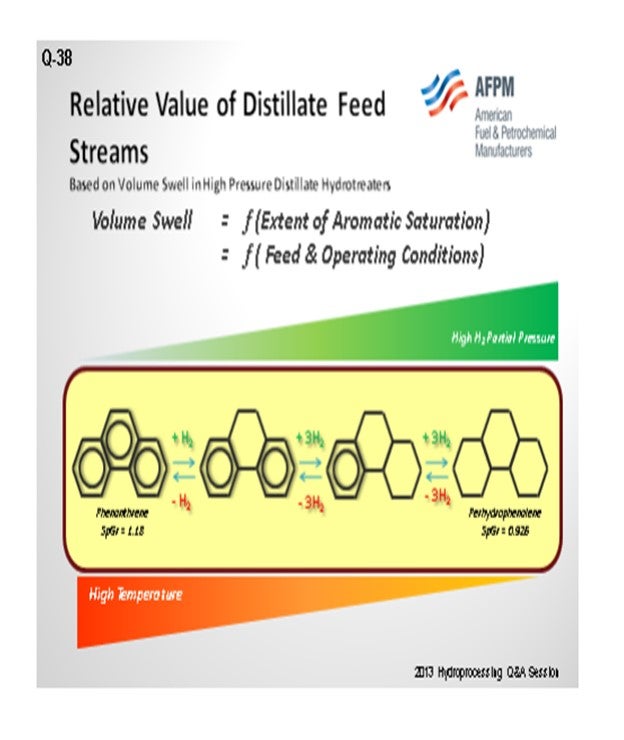

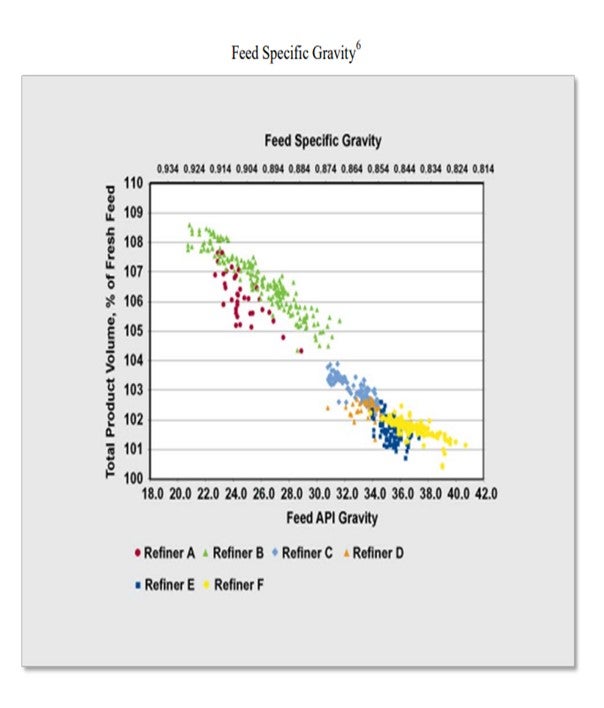

The question asks specifically about high-pressure ULSD service. ‘High pressure’ means the reactor has to operate around 1,000 pounds without any problem supplying hydrogen to these units. The relative value of the volume swell depends on how much you can saturate aromatics. This aromatic saturation is an equilibrium reaction, so you need high hydrogen partial pressure on the lower temperature side. If the temperatures are too low, you do not have the proper reaction rate; you have to be right at the peak. If the temperature is too high, then you will go the opposite way: Instead of saturating, you will de-saturate.

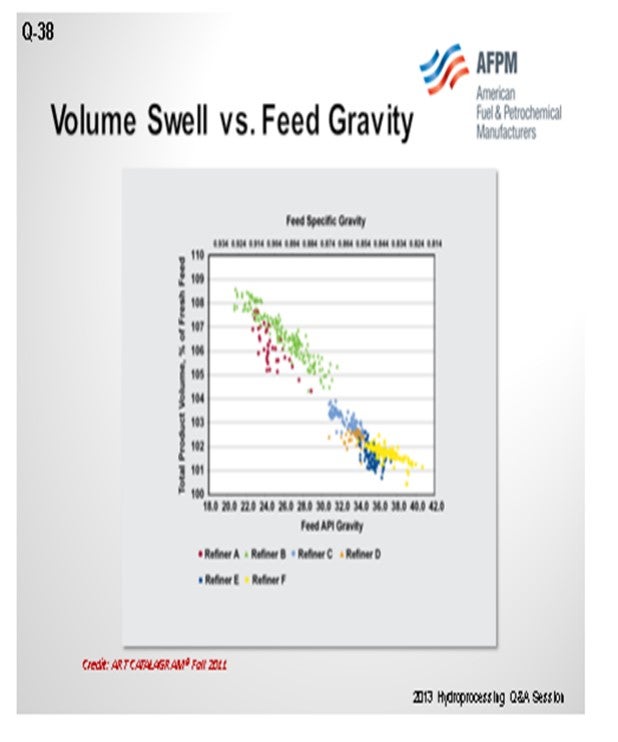

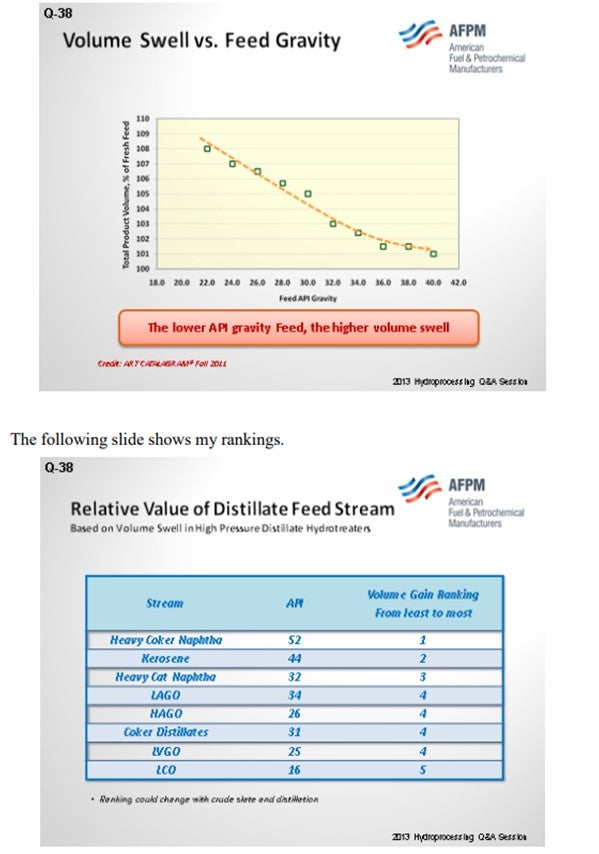

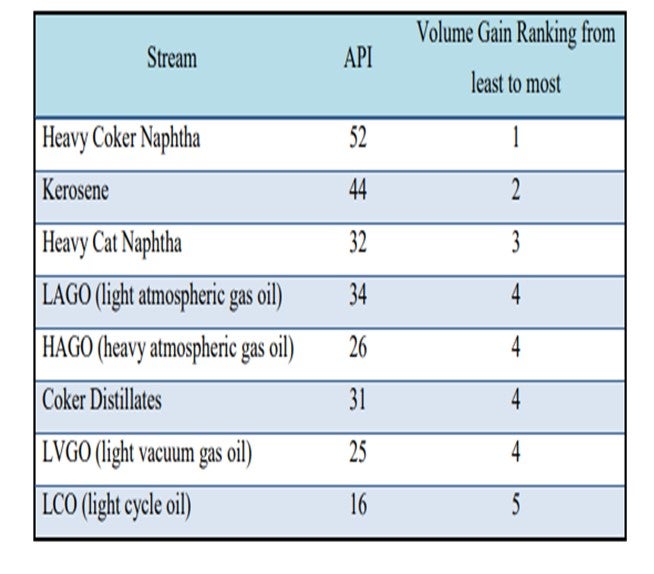

I am showing this graph from the 2011 ART CATALAGRAM® because I believe it answers the questions. You can see that the lower the API gravity, the higher the volume gain of a diesel stream. When plotted, you see that it is the same picture, just repeated. You want those two values. Heavy coker naphtha, which has a high API gravity, will show the smallest volume gain, followed by kerosene and heavy cat naphtha, and then other distillate feeds.

The feeds with a high API will have a lower volume gain. LCO (light cycle oil) has the maximum volume gain. Coker distillates do have a lot of cracked material inside, mostly olefins, but also contain a lot of sulfur and nitrogen, which, when removed, become volume loss.

LIOLIOS (DuPont Clean Technologies)

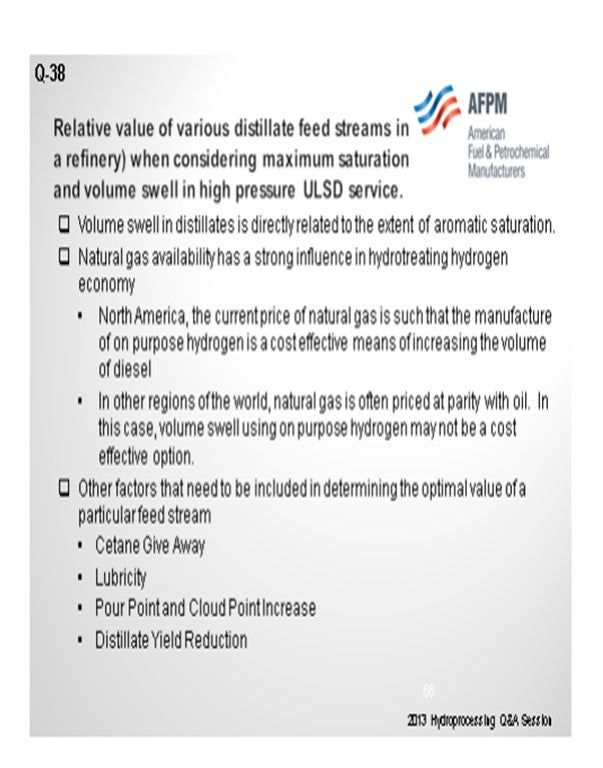

We agree with those comments. I want to add the information shown in bold at the end of the slide. As you consider what you are going to do with those particular feeds, you must look at cetane giveaway. As you do more saturation, you need to determine if you exceeding your cetane rating, resulting in some giveaway there. Although lubricity from oversaturation does not necessarily lead to reduced fuel lubricity, there is certainly a lot of discussion in that area. Oversaturation can lead to pour point and cloud point issues as you convert more of the compounds. Then depending on your feedstocks, you will end up making more light ends and less desirable products. Again, it is all economics, but the primary driver for volume swell really is the availability and cost of hydrogen.

SIVADASAN (UOP LLC, A Honeywell Company)

I do not have much to add on except one point: that the product qualities obtained when you are processing a cracked stock might be poor and may require further treatment or blending in the downstream units.

MONTRI VICHAILAK (Marathon Petroleum Corporation)

Volume swell in distillates is directly related to the extent of aromatic saturation. Aromatics content of distillates material is also directly related to its density (API). The lower the API gravity means the higher aromatics content, and vice versa. Below is the list of API for each of the distillates hydrotreater feed’s components.

Saturation of olefins and diolefins also give volume gain in the range of 2 to 4%. Aromatic saturation generates at a minimum of 9 to 10% volume gain depending on how many aromatic rings get saturated. Therefore, streams that contain higher, polycondensed aromatics will generate more volume gain in high-pressure ULSD services. Removal of heteroatoms (sulfurs) creates mass loss, and that usually means volume loss.

Aromatic saturation reactions are equilibrium reactions. The ability to saturate multi-ring aromatics depends not only on operating condition, but also on feed composition. Higher saturates rings in feed will give less aromatic conversion than lower saturates rings in feed. Thus, straight-run material in feed will limit volume expansion potential. Therefore, straight-run material should be minimized to process in high-pressure units in order to maximize volume gain. The cost of hydrogen is also important. When hydrogen costs return to historical patterns, volume swell will be much less attractive.

Crude sources also impact the aromatic content in distillates cut. However, for a particular type of crude source, straight-run material normally contains the least amount of aromatics. Thermal cracking material (i.e., coker) contains significant amounts of olefinic and diolefinic materials. Light cycle oil (LCO) from catalytic cracking has the highest content of aromatics comparing to other distillates sources.

GLENN LIOLIOS (DuPont Clean Technologies)

DuPont agrees with the response from Marathon on the relative value of the different distillate feed streams related to volume swell. However, the availability of natural gas in North America has dramatically changed the hydrogen production economics and its impact on hydrotreating.

Cost of hydrogen and geographical location of the hydrotreater are also important variables to determine the economics of the volume swell. For example, in North America, the current price of natural gas is such that the manufacture of on-purpose hydrogen is a cost-effective means of increasing the volume of diesel. However, in other regions of the world, natural gas is often priced at parity with oil. In this case, volume swell using on-purpose hydrogen may not be a cost-effective option.

Other factors that need to be included in determining the optimal value of a particular feed stream when considering volume swell in the current low natural gas price environment in North American are:

• Cetane Giveaway: Saturation of aromatic and olefin compounds will result in an increase not only in volume, but also cetane ratings. While generally desirable, if cetane levels are higher than the distillate pool requirements, the operating cost or capacity restrictions may not justify either the volume swell or cetane boost.

• Lubricity: In general, oversaturation and the subsequent reduction in aromatic compounds, especially polynuclear aromatic and aromatic nitrogen compounds, can result in fuel lubricity issues. Lowering sulfur, nitrogen, or aromatics per se does not necessarily lower fuel lubricity; but in general, these compounds are known to have better lubricity than aliphatic compounds.

• Pour Point and Cloud Point Increase: Oversaturation may also increase pour and cloud points as aromatic compounds are converted to naphthenes or paraffinic compounds.

• Distillate Yield Reduction: The increase in reactor severity to achieve higher aromatic and olefin saturation can increase the conversion of distillate to lighter less valuable products such as naphtha and LPG. The higher severity can also increase catalyst aging and thereby reduce reactor run-length.

RAJESH SIVADSAN (UOP LLC, A Honeywell Company)

The biggest swell potential is in the cracked stock feeds. The streams constituting the cracked diesel (coker and LCO) will have the highest volume expansion and hydrogen uptake and will have the highest upgrade across the units. But product qualities from these streams are poor relative to processing straight-run, so it may be harder to meet tight specs. Consequently, refineries should really run an economic analysis.

DAVID VANNAUKER (Haldor Topsøe, Inc.)

Many sites have built new high-pressure units to meet the ULSD specifications for feed blend with lots of cracked stocks and high endpoints. The primary benefit is that the higher pressure improves the aromatic saturation and thus the kinetics for removing the difficult dibenzothiophene (DBT) sulfur species. The high-pressure units should process the heavy virgin distillates, such as the heavier component of the light cycle oil and the heavier component of the light coker gas oil. The wide range of virgin kerosene and diesel boiling material and coker and FCC diesel and kerosene boiling range molecules should be processed in the lower pressure units.

From the perspective of volume swell, the streams with the highest aromatic contents should be processed in the high-pressure unit. The highest volume swell is realized with FCC streams, followed by coker and then virgin streams. To maximize diesel production, one needs to consider the boiling range. Since converting an aromatic molecule to a naphthene reduces the boiling range, light aromatics upon saturation may move out of the diesel boiling range and into the naphtha range. For a site trying to maximize overall diesel production, this is another justification for having the lightest diesel boiling range cracked stocks in lower pressure units. When aiming for maximum volume swell, it is, of course, very important to have the required hydrogen availability to avoid hydrogen starvation.

LARRY KRAUS (Criterion Catalysts & Technologies)

When considering maximum saturation and volume swell in a high-pressure ULSD unit, hydrogen-deficient light cycle oil and coker light gas oil offer the largest opportunities for consumption of low-cost H2 to increase product volume. However, the ability to utilize these feeds is dependent on the availability of H2 at the unit, cetane constraints, and the desired cycle life. Optimizing cutpoint of the light cycle oil and coker light gas oil streams can improve volume swell within these constraints.

Straight-run diesel is valuable for its lower density and higher cetane characteristics; however, its low aromatic content limits its H2 consumption/volume expansion potential. Upgrading light vacuum gas oil has high value and increased potential for volume expansion potential versus straight-run gas oil when pushing the T-90 point to the maximum specification. Lastly, light feeds are valuable when they can be used to expand the distillate pool up to the flashpoint limit. Light products can have deleterious effects on ULSD operations by increasing H2 consumption through olefin saturation and reducing the hydrogen partial pressure through vaporization.