Question 36: Which refinery water sources do you accept for hydrotreater water wash (e.g., stripped fractionator overhead water, stripper sour water, etc.)? What are typical water quality guidelines?

JEFFREY MUELLER (Marathon Petroleum Company)

Waterwash systems must be designed well, with good water contact and draining, or the wash can create significant corrosion concerns, potentially resulting in process safety incidents. MPC experienced this first-hand with an intermittent wash system on an NHT unit. Though there were many issues identified as causal factors during this incident, the design of the waterwash system played a part in the failure.

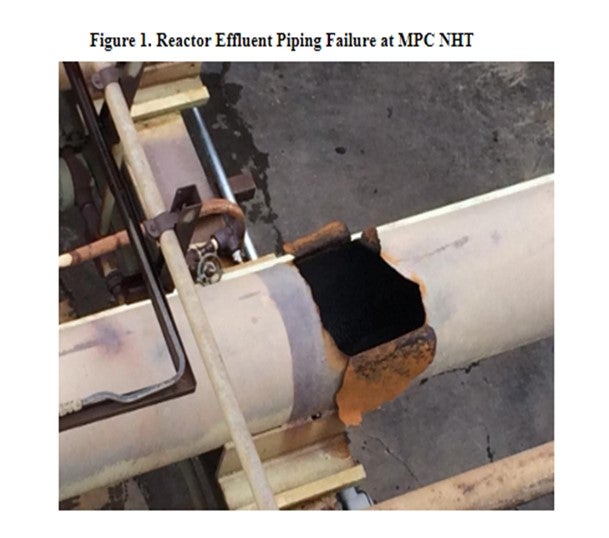

On April 9, 2015, a failure occurred on the top of a horizontal section of reactor effluent piping of a naphtha hydrotreater. The escaping stream of hydrocarbon was estimated to be 70 to 80feet high, and the sound of liquid hydrocarbon release made communications in the immediate area difficult. Fortunately, the unit operators were able to shut down the heaters without incident. Figure 1 illustrates the piping failure associated with this incident.

The piece of piping that failed was located directly downstream of the feed/effluent exchangers and a continuous waterwash injection point, upstream of the reactor effluent air coolers. The systemoperated at 320 psig and 280°F, with no prior history of leaks. The process, at this point, contained 0.2 mol% H2S, 0.001 mol% NH3, and 0 to 4 ppm chloride in the makeup hydrogen. These conditions are not severe by hydrotreater standards.

The failure was internal corrosion due to the condensation of HCl on the vapor space of the pipe. Some of the causal factors in this incident relate to the waterwash design (though this was not the exclusive cause). The presence of water with inadequate mixing created an extremely corrosive condition in the vapor space of the horizontal pipe. A couple physical factors related to the waterwash contributed to this inadequate mixing:

*The water was injected through low velocity quills.

*Water was injected upstream of a non-freedraining low point with long horizontal line.

*Typically, waterwash is injected immediately upstream of the REACs. In this case, there was a long horizontal run of piping immediately downstream of the injection that does not allow for adequate mixing.

CHRIS STEVES (Norton Engineering)

Refiners typically use stripped sour water or boiler feedwater as hydrotreater washwater. While stripped sour water is usually cheaper and of adequate quality for hydrotreater washwater, it may not be available at high enoughpressure for use as hydrotreater washwater, and BFW (boiler feed water) may be available at the desired pressure from existing equipment.