Question 35: Does the panel have any experience intentionally producing a ‘heavy’ alkylate stream? What are the disposition options for this stream?

PIZZINI (Phillips 66)

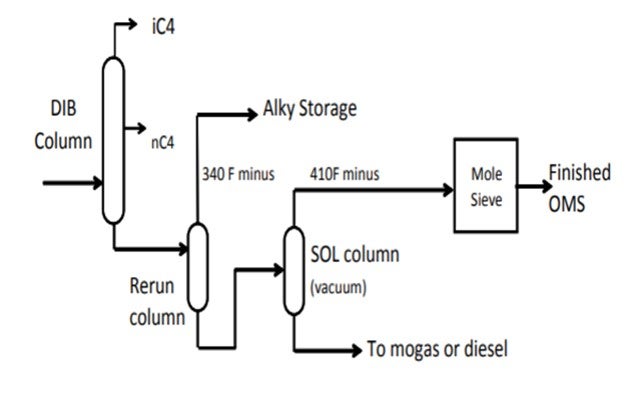

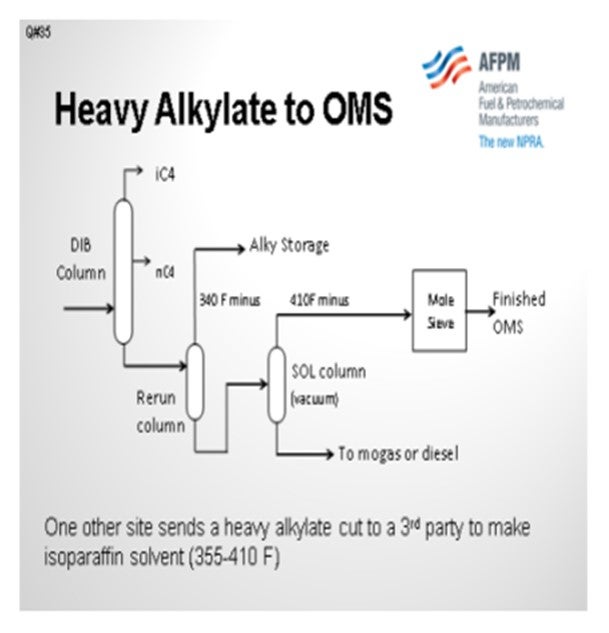

Phillips 66 has one location that makes odorless mineral spirits (OMS), starting with the raw alkylate off of the deisobutanizer column. We take those bottoms through a rerun where we drive off to 340ºF, and then that stream goes right back into alkylation unit storage. The second fractionation step is done under a vacuum. Now we take the 410ºF overhead. Anything heavier can be routed to the mogas (motor gasoline); or if it has enough heavy content, we can put it in the diesel stream if we are getting a higher margin for diesel fuel than for gasoline. So that bottom stream off of the SOL (safe operating limit) column can go either way: to mogas or to diesel.

The stream that ends up as OMS is put through a molecular sieve which takes out the water and the sulfur. A typical yield relative to alkylate is about 3% for this unit. We have a few other sites that split alkylate generally to make aviation gasoline with a light fraction in at least one location that sends the heavy fraction to a third-party. The third-party then turns that into an isoparaffin solvent.

PIZZINI (Phillips 66)

One of the Phillips 66 sulfuric acid alky units produces odorless mineral spirits from heavy alkylate. A portion of the deisobutanized alkylate is routed to a fractionator where 340°F minus material is driven overhead and returned as alkylate product. The higher boiling point material is fed to a second fractionation column which separates material with an approximate boiling point of less than 410°F from material with higher boiling points. The lower boiling point

material is treated to remove water and sulfur and is sent to product storage as odorless mineral spirits (OMS), an FDA approved solvent. The higher boiling point material is sent to light gas oil or to gasoline. The odorless mineral spirits can also be routed into diesel if the economics dictate.

Typical OMS yield on alkylate is around 3% (see simplified flow diagram below). Three of our other sites generate a light alkylate cut as an aviation gasoline blend stock. Two send bottoms to mogas, and the third sends bottoms to a third-party to make isoparaffin solvent 355°F to 410°F.