Question 3: What type of release mitigation safety systems do you use for sulfuric acid and HF alkylation units?

LANCE TALLMAN (CITGO Petroleum)

HF

-

Rapid Acid De-Inventory systems to move HF acid from unit to remote acid storage drums

-

Acid Settler, reactor risers and coolers (includes unit shutdown)

-

Acid Storage Drum

-

Water Curtain surrounding high acid area of unit (with auto-activation)

-

Water deluges on Acid Settler, Remote Acid Storage Drums and acid-service pumps

-

Elevated, remotely operable fire monitors with independent supplemental water supply

-

Camera systems to improve response time

-

Point source hydrocarbon detectors

-

Point source HF detectors

-

Bi-level perimeter laser HF detectors

-

Remote capabilities to start, stop, isolate, vent to flare and deluge acid-service pumps

-

Remote control panel for acid truck unloading (isolation valves)

-

Closed circuit monitoring of unit

-

Sulfuric Acid

Sulfuric acid alkylation units do not require the robust safety systems as the HF Alky units since sulfuric acid is a liquid at atmospheric conditions. The release mitigation safety systems typically used are curbed and/or diked areas to contain the liquid sulfuric acid in event of a leak. This exists in the reaction section, blowdown section, and fresh/spent acid tanks. The same mitigation systems are in place in the effluent treating section and the depropanizer feed treating system where caustic is present. When Operators respond to any release, they’re equipped with the appropriate PPE, which include slicker suit, face shield, and proper gloves. In addition, hydrocarbon detectors are present in and around the unit due to the presence of LPGs.

SHANE PRESLEY (DuPont)

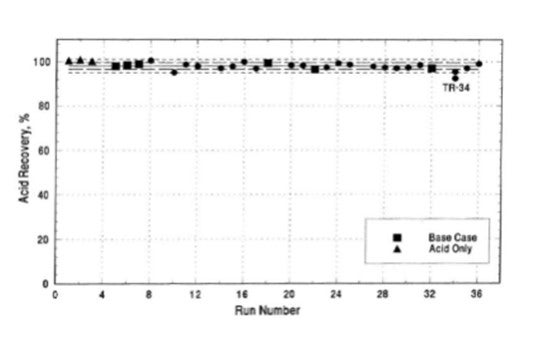

Sulfuric acid is a liquid at atmospheric conditions and will pool if released rather than form a vapor cloud. During the summer of 1991 an independent consultant performed a series of large-scale sulfuric acid leak tests. In all, thirty-six release tests were conducted, three tests utilizing alkylation equilibrium acid from an operating commercial alkylation unit and thirty-three tests using an acid/hydrocarbon emulsion. The tests involving equilibrium acid resulted in essentially 100% recovery of the acid released; the remaining tests resulted in an average 97.6% recovery of the acid released (Figure 1) [1].

Figure 1: Sulfuric Acid Test Recovery

Because sulfuric acid will pool when released rather than forming a toxic vapor cloud, only basic mitigations are required. These mitigations typically include curbed and/or diked areas around sections of the unit containing sulfuric acid to contain the acid in the event of a leak. These areas typically include the reaction section, acid blowdown section, and fresh/spent acid storage areas. In the event of small or minor leaks, sulfuric acid can be neutralized with soda ash before removal. Larger spills may require physical removal of the acid. Other release mitigation systems in place are not specific for sulfuric acid and are typical for other processing units containing LPG hydrocarbons.