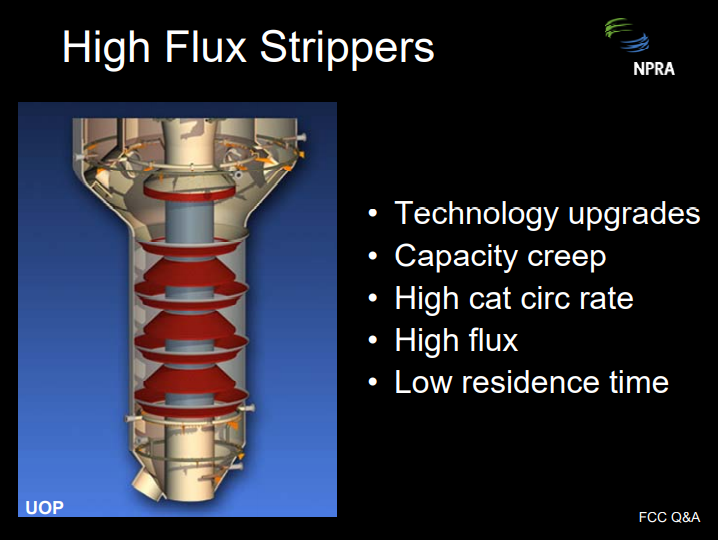

Question 19: FCC revamps commonly include technology upgrades, which increase the catalyst circulation rate, which then increases the stripper flux and reduces the stripper residence time. Please describe your experience with the high flux stripper and its performance. What is the maximum flux you have achieved? What is the minimum residence time you have achieved? Will the use of high efficiency stripper internals reduce the required residence time?

WALKER (UOP)

In addition to technology upgrades, capacity creep is a major factor contributing to ever-higher catalyst circulation rates. Together, these factors are indeed forcing refiners to push the boundary of stripper flux and residence time experience.

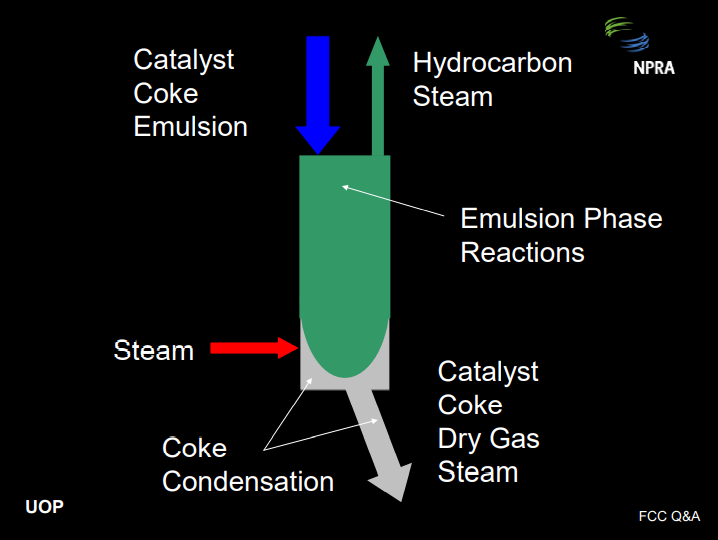

The basic function of the stripper is to recover hydrocarbon product from the emulsion phase, which is entrained with the catalyst after it leaves the riser termination device. This is done using steam that is distributed into the bottom of the stripper. As catalyst leaves the riser termination device, it carries with it hydrocarbon vapors in the emulsion phase. These hydrocarbons should be stripped out as quickly as possible for two reasons. First of all, if the hydrocarbon is not stripped out, it will enter the regenerator and burn there. This will increase the regenerator temperature, reduce the cat-to-oil ratio, drive down conversion, and increase dry gas: all bad things. Secondly, the hydrocarbon vapors in the emulsion phase will continue to react non-selectively in the stripper dense bed, depressing product value.

A catalyst stripper can be readily compared with a reactive distillation column. The emulsion phase and the coke are both reactive. However, the reactions in the stripper are more selective to dry gas and coke compared with the reactions in the riser, so we want to suppress these reactions. The objective is to strip out the emulsion phase as quickly as possible. The coke condensation reactions will continue all the way down the spent standpipe, producing dry gas all along the way, but these are not as harmful as the emulsion phase reactions.

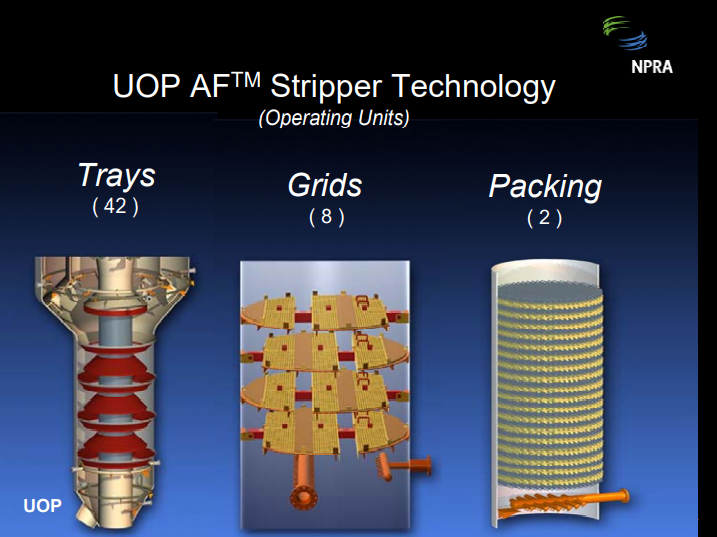

As with ordinary distillation columns, stripping efficiency can be improved by increasing the stripping steam rate, increasing the number of stages, which requires more volume and residence time, or improving the efficiency of each stage. So the answer is yes, use of modern, high efficiency internals will definitely reduce the required residence time.

At UOP, we have several strippers operating at 90 Mlb/hr/ft2 to 120 Mlb/hr/ft2 flux, with corresponding residence times of 35 seconds to 45 seconds. We have two operating right at 120 Mlb/hr/ft2 and one in design for around 130 Mlb/hr/ft2 . Generally, we have observed that strippers with very long residence times do not respond to decreasing stripper level. However, with some stripper internals, we do see a negative response to lower levels for strippers with very short residence times; i.e., under 60 seconds. So this observation does demonstrate that there is a real penalty for ever-shorter residence time strippers and the need for high efficiency internals.

ASDOURIAN (Sunoco Inc.)

I will just speak qualitatively to these questions. High flux stripping has occurred in several of our FCCUs. We found that our annular strippers are most vulnerable. Strippers have been upgraded by adding stages, modifying steam distribution, adding a means for radial catalyst distribution, and/or adding more cross-sectional flow area. Prior to the upgrades, hydrogen and coke ran higher than desired, and obviously these changes improved that situation. Also, regenerator temperature and flue gas percent CO was very sensitive to stripper level and/or stripping steam rates. Upgrades have resulted in the less sensitivity stripper conditions, as well as the lower hydrogen and coke. Also, another side benefit of this is that it results in a reduction in the sour water make if sour water management or conservations are an issue.

SALIP SONI (ABB Lummus)

I think there is some clarification required regarding what the residence time really means because in some strippers—like the conventional design backwards—the residence time is calculated based on the total volume of the stripper, but effective volume is much lower because the stripper area is reduced to the cross-sectional area of the stripper. The catalyst is moving faster than if the whole cross-section area was available to flow. So, I would call that a superficial residence time, but the technical residence time is slower. And if you install the modern devices, they add volume for the catalyst to flow or the cross-section area for the catalyst to flow through, then the catalyst will be flowing slower. Though the residence time appears slower, based on the stripper volume, effective residence time is probably the same. So, Lummus has installed the new advanced modular grade stripper internals in the stripper where residence time is only 30 seconds. It improved the performance of the stripper and reduced the stripping steam rate.